Ultimate Guide to Hydroponic Water Management in Commercial Greenhouses.

This extensive guide combines scientific knowledge, practical applications, and real-world case studies to provide a detailed understanding of hydroponic water management for commercial growers. Data-driven water quality optimization for commercial hydroponics impossible without tips and tricks we describe in this post. Read now and improve your growing operations.

Step 1: How to optimize your hydroponic water system for maximum efficiency and yield

1.1. Regular Water Quality Testing

Why It Matters?

Testing water quality regularly is like giving your plants a regular health check-up. The pH level determines how nutrients dissolve and become available to plants. Ideal pH levels (usually between 5.5 to 6.5) ensure that plants can absorb all the necessary nutrients. EC (Electrical Conductivity) and TDS (Total Dissolved Solids) measurements indicate the total amount of nutrients in the water. If the concentration is too high, plants may suffer from nutrient burn, while too low means they’re missing out on essential nutrients.

Advanced tools like DO and ORP sensors offer deeper insights into the well-being of your system. Monitors dissolved oxygen, crucial for healthy root growth and nutrient uptake. Low DO can stress plants and limit yield. ORP measures the redox potential, indicating the water’s oxidizing or reducing capacity, affecting nutrient availability and microbial activity.

Balancing Ions: Maintaining an optimal ionic balance is critical. If certain nutrients are too dominant, they can inhibit the absorption of others, leading to deficiencies and imbalances. The key balancing ions crucial for plant nutrition include macronutrients like nitrogen (N), potassium (K⁺), and calcium (Ca²⁺), as well as micronutrients such as iron (Fe²⁺/Fe³⁺) and manganese (Mn²⁺). Maintaining an optimal ionic balance is critical, as imbalances can inhibit nutrient absorption, leading to deficiencies. Regular monitoring and adjustment of nutrients like nitrogen, potassium, and calcium, alongside pH and electrical conductivity levels, ensure a healthy, productive hydroponic system.

Tools: pH, EC, TDS meters, Dissolved Oxygen (DO) sensor, Oxidation-Reduction Potential (ORP) sensor (For advanced growers).

Advanced Monitoring:

- DO sensor: Aim for 5-7 ppm for optimal root growth and nutrient uptake. Adjust aeration systems based on readings.

- ORP sensor: Maintain a range of 200-350 mV for most plants. Higher values indicate potential disease risk, while lower values might suggest nutrient imbalances.

Choose the level of monitoring that fits your needs and expertise. Whether you’re a beginner or an advanced grower, mastering water chemistry is key to thriving hydroponic plants!

Adjusting the pH of the nutrient solution in hydroponic systems is a critical aspect of ensuring optimal plant growth and nutrient uptake. The pH level can significantly affect the solubility and availability of nutrients.

Understanding pH and Nutrient Availability

- pH Range and Nutrient Solubility: The solubility of various nutrients is dependent on the pH of the solution. If the pH level strays too far from the optimal range, certain nutrients can become less available or completely unavailable to plants. This can lead to nutrient deficiencies, even if these nutrients are present in sufficient quantities in the solution.

- Scientific Insight: For instance, at a higher pH level, micronutrients like iron, manganese, boron, copper, and zinc become less available due to precipitation or conversion to forms that plants can’t absorb. Conversely, at a lower pH, macronutrients like nitrogen, phosphorus, and potassium can become overly available, potentially leading to toxicity.

Suggested Table for Nutrient Availability and pH Levels

| Nutrient | Optimal pH Range for Availability |

| Nitrogen (N) | 6.0 – 7.0 |

| Phosphorus (P) | 6.5 – 7.5 |

| Potassium (K) | 5.5 – 7.5 |

| Calcium (Ca) | 6.2 – 7.0 |

| Magnesium (Mg) | 5.5 – 7.5 |

| Sulfur (S) | 5.5 – 7.5 |

| Iron (Fe) | 5.0 – 6.5 |

| Manganese (Mn) | 5.5 – 6.5 |

| Boron (B) | 5.0 – 6.0 |

| Copper (Cu) | 5.0 – 6.5 |

| Zinc (Zn) | 5.5 – 6.5 |

| Molybdenum (Mo) | 5.5 – 7.5 |

Adjusting pH for Optimal Nutrient Uptake

Procedure: Regularly monitor the pH of the nutrient solution – automated pH and EC monitoring for commercial hydroponics save lots of resources and time. If adjustments are needed, use pH up or down solutions gradually, mixing thoroughly and retesting the pH after each adjustment.

Frequency and Amount: The frequency and amount of adjustment depend on several factors, including the type of plants being grown, the initial pH of the water, and the composition of the nutrient solution. It’s important to make gradual changes to avoid shocking the plants.

Step 2: Nutrient Management for Peak Performance

2.1. Choosing the Right Nutrients

What to Look For: Advanced commercial growers recognize that effective nutrient management is not just about providing the right nutrients, but also about understanding the intricate dynamics between these nutrients, the growing medium, and the plant’s developmental stage.

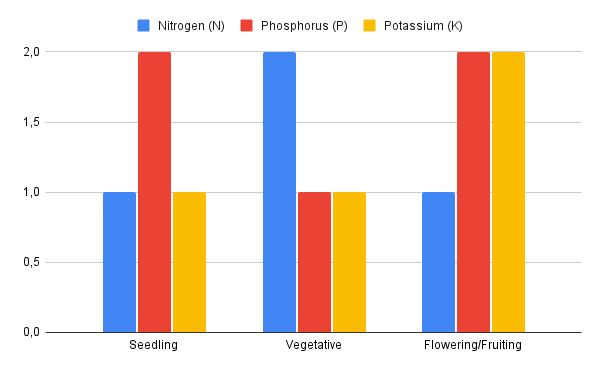

Nutrient Types and Ratios: Different plants have unique nutritional requirements which vary not only by species but also throughout different growth stages. For instance, leafy greens often require higher nitrogen levels during the vegetative phase, while fruiting plants like tomatoes might need increased potassium and phosphorus during the flowering and fruiting stages.

Formulations for Different Growth Stages:

- Seedling Stage: Nutrient solutions should be lighter, with a higher ratio of phosphorus to promote root development.

- Vegetative Stage: Increased nitrogen is crucial for leaf and stem growth.

- Flowering and Fruiting Stage: Higher potassium and phosphorus levels are necessary to support flower and fruit development.

Chelated Nutrients: Chelation is a process where nutrients are bound to organic molecules, enhancing their availability to plants. Chelated forms are particularly beneficial in hydroponic systems as they remain soluble and accessible over a broader pH range.

Tailoring to Plant Needs:

- Custom Blends: Advanced growers often create custom nutrient blends tailored to their specific crop’s needs. This involves understanding the nutrient uptake profile of the plant and adjusting the N-P-K ratios accordingly.

- Micronutrients: While N-P-K is the primary focus, micronutrients like iron, manganese, zinc, copper, molybdenum, and boron are equally important. The precise control of these micronutrients can significantly impact plant health and yield.

- pH and Nutrient Availability: Maintaining the nutrient solution at the right pH is crucial as it affects nutrient availability. A slightly acidic pH (5.5 to 6.5) is generally optimal for most hydroponic systems, but some crops may have specific needs.

Advanced Techniques for Nutrient Optimization:

Electrical Conductivity (EC) Management: Monitoring the EC of the nutrient solution allows for precise control of nutrient strength. Adjusting EC based on plant growth stages can optimize nutrient uptake.

Nutrient Solution Temperature: The temperature of the nutrient solution can affect nutrient uptake. Keeping the solution at an optimal temperature (usually around 18-22°C or 65-72°F) ensures that plants can absorb nutrients efficiently.

Use of Organic Nutrients: While hydroponics traditionally relies on inorganic salts, there is a growing interest in incorporating organic nutrients. These can improve plant resilience and flavor but require careful management to prevent system clogs and maintain the balance of microorganisms in the system.

System Flushing: Regular flushing of the system with plain water can prevent the buildup of excess salts and reduce the risk of nutrient lockout, where plants are unable to absorb certain nutrients due to imbalances.

Monitoring and Adjusting: Constant monitoring and adjustment of the nutrient solution is paramount. This involves regular testing of pH, EC, and concentration of individual nutrients using advanced tools like spectrometers or ion-selective electrodes. Data-driven adjustments ensure that plants receive the optimal nutrient mix at all times.

Integration of Technology: Utilizing smart hydroponic water management for high-value crops with sensors and AI algorithms can automate the process of nutrient adjustment, ensuring real-time optimization based on the plants’ uptake and environmental conditions. Automated pH and EC monitoring for commercial hydroponics reduce repetitive tasks and save less manual labor!

2.2. Proper Nutrient Mixing

How to Do It: Properly mixing your nutrients ensures that your plants receive a balanced diet. It’s like cooking a well-rounded meal. Follow the manufacturer’s instructions to avoid any chemical imbalances. Incorrectly mixed nutrients can precipitate out of the solution, becoming unavailable to plants and potentially causing harm.

The Science of Nutrient Mixing

- Chemical Interactions: Nutrients in hydroponic solutions are in ionic form, which means they can interact with each other. Some combinations can lead to precipitation, where nutrients fall out of the solution and become unavailable to plants. This is often seen with calcium and phosphates or sulfates.

- Solubility Factors: The solubility of nutrients can change with temperature, pH, and concentration. For example, solubility can decrease at lower temperatures, leading to precipitation.

The Art of Nutrient Mixing

- Sequential Mixing: Add nutrients to your water one at a time, ensuring each is fully dissolved before adding the next. This prevents nutrient interactions that can cause precipitation.

- Water Quality: Start with water of known quality. High levels of certain ions in tap water can react with added nutrients. In some cases, using filtered or reverse osmosis water may be necessary.

- Temperature Considerations: Mix nutrients at a temperature close to what your plants will experience. This helps ensure that all nutrients remain soluble under growing conditions.

Advanced Tips

- Concentration Monitoring: Use tools like refractometers or EC meters to monitor nutrient concentrations. This helps ensure consistency across batches.

- pH Management: After mixing, check and adjust the pH of your solution. The ideal pH range for most hydroponic systems is between 5.5 and 6.5, but this can vary depending on the crop.

- Micro and Macronutrients: Pay attention to both macro (N-P-K) and micronutrients. Micronutrients are needed in smaller quantities but are just as essential for plant health.

- Regular Reservoir Changes: Change your nutrient solution regularly to prevent the buildup of harmful byproducts or imbalanced nutrient ratios.

- Tailoring to Plant Stages: Adjust nutrient formulations based on plant growth stages—seedling, vegetative, flowering, and fruiting stages all have different nutrient requirements.

- Record Keeping: Keep detailed records of nutrient mixes, pH levels, EC values, and plant responses. This data is invaluable for refining your nutrient management strategy.

2.3. Consistent Monitoring of Nutrient Levels

Tools and Techniques: Regularly check nutrient levels using EC/TDS meters. High EC levels indicate too many nutrients, which can lead to nutrient burn, while low levels suggest your plants are not getting enough. Monitoring and adjusting nutrient levels ensure your plants grow healthy and strong.

Step 3: Optimizing Water Temperature – Hydroponic Water Management For High-value Crops

3.1. Keeping an Eye on Temperature

- Why Temperature Matters: Water temperature is vital for plant health. It affects oxygen levels in the water, with cooler water holding more oxygen. Additionally, the temperature influences the metabolic rate of plants and their nutrient uptake. Keeping water between 65-75°F ensures plants have enough oxygen and are metabolically active.

3.2. Temperature Control Equipment

- Water Temperature Sensors.

- Using Heaters and Chillers: Depending on your climate, you might need water heaters or chillers to maintain stable temperatures. Sudden temperature changes can shock plants, so it’s crucial to keep the water temperature consistent.

Step 4: Ensuring Adequate Oxygenation

4.1. Why Oxygen is Key

Roots need oxygen to respire and absorb nutrients effectively. In waterlogged or oxygen-poor conditions, plants can become stressed, leading to stunted growth or root diseases. Aeration, typically achieved with air stones and pumps, introduces oxygen into the water, creating an ideal environment for roots to thrive.

Dissolving Oxygen Levels:

- Water circulation: Ensure proper water movement through pumps and agitation systems to facilitate oxygen absorption from the air.

- Oxygen supplementation: Introduce pure oxygen via diffusers or directly bubble air into the nutrient solution using air pumps and air stones.

- Water management: Avoid overwatering to prevent waterlogging and encourage air pockets in the root zone.

- Substrate selection: Choose well-draining substrates like perlite or coconut coir to promote air circulation around the roots.

Monitoring and Measurement:

- Dissolved oxygen sensor: These device directly measure oxygen levels in the water. Aim for levels between 5-7 ppm for optimal plant growth.

- Visual indicators: Stunted growth, yellowing leaves, and root rot can suggest oxygen deficiency. Regular inspections can provide early warnings.

- Automated systems: Invest in advanced monitoring systems that continuously track oxygen levels and trigger alarms if they fall below acceptable thresholds.

Step 5: Filtration and Sterilization for Plant Health

5.1. Implementing Effective Filtration Systems

Types of filters: Mechanical filters remove physical particles from the water, preventing clogs and maintaining clarity. Biological filters use beneficial bacteria to break down harmful organic compounds, keeping the water healthy for plants.

Clean water means healthy roots. Algae and other pathogens can compete with plants for nutrients and light, so filtration is essential to keep these at bay.

5.2. Sterilizing Hydroponic Water

Sterilizing Hydroponic Water: Essential for Advanced Commercial Greenhouses

In the advanced commercial hydroponic greenhouse sector, sterilizing hydroponic water is a pivotal process that can greatly influence plant health and overall yields. This practice involves using various sterilization methods to eliminate harmful pathogens from water, ensuring a clean and disease-free environment for hydroponic systems.

Different Types of Commercial Sterilizers for Hydroponic Water Management Systems

- UV Sterilizers: UV (Ultraviolet) sterilizers are widely used for sterilizing hydroponic water due to their effectiveness in neutralizing bacteria, viruses, and fungi. They work by exposing water to UV light, which disrupts the DNA of pathogens, rendering them harmless.

- Ozone Generators: These devices infuse ozone into the water, a powerful oxidant that eliminates contaminants. Ozone generators are particularly effective against a broad spectrum of microorganisms and also help in breaking down accumulated organic matter in water systems.

- Chemical Sterilizers: In some settings, chemical-based sterilizers, such as hydrogen peroxide or chlorine-based solutions, are used. These chemicals can be effective but must be managed carefully to avoid residue that could affect plant health.

Impact of Sterilizing Hydroponic Water on Plants and Yields

Sterilizing hydroponic water plays a crucial role in maintaining the overall health of the plants. By removing harmful pathogens, these sterilization methods prevent the outbreak of diseases, which can significantly impact plant growth and crop yields. Healthy plants are more productive, leading to increased yields.

Moreover, sterilizing hydroponic water also contributes to a more stable and controlled growing environment. This stability is key in commercial hydroponic greenhouses, where consistent production and high-quality yields are essential.

Step 6: Regular System Maintenance

Maintaining a hydroponic system is crucial for ensuring its longevity and optimal functioning. For commercial growers, regular system maintenance is not just about preserving the system but also about maximizing plant health and yield. Here’s a detailed approach to system maintenance:

6.1. Cleaning and Upkeep: Preventing Algae and System Clogs

Detailed Cleaning Procedures

- Reservoir Maintenance: Clean your nutrient reservoir every 1-2 weeks. Use a non-toxic cleaner to remove any residue or biofilm. Ensure the reservoir is free of debris and sediment that can clog the system.

- Pipe and Emitter Cleaning: Inspect and clean pipes and emitters regularly. Use brushes or specialized cleaning solutions designed for hydroponic systems to remove any blockages or buildup.

- Algae Control: Algae growth can be minimized by controlling light exposure to nutrient solutions and by regularly cleaning the system. Consider using algaecides that are safe for plants if necessary.

- Root Zone Maintenance: Regularly check the root zones of your plants for signs of rot or disease. Clean and trim roots if necessary to maintain healthy growth.

Best Practices

- Schedule regular maintenance to prevent issues from becoming significant problems.

- Keep a log of maintenance activities to track the health and performance of your system.

6.2. Flushing Out the System: Ensuring Nutrient Balance

Flushing Procedure

Flush your hydroponic system every 2-4 weeks, depending on the crop and system type. Run clean, pH-balanced water through the system for a period, usually 1-2 hours, to remove any salt and nutrient buildup. After flushing, refill the system with fresh nutrient solution, ensuring it’s properly balanced and pH-adjusted.

Importance of Flushing

- Nutrient Balance: Regular flushing helps maintain an optimal nutrient balance, preventing toxicity or deficiencies.

- System Health: Flushing keeps the internal components of your hydroponic system clean, reducing wear and tear.

Tips for Effective Flushing

Use a conductivity meter to check the EC levels before and after flushing to ensure all excess nutrients are removed. Adjust the frequency of flushing based on your observations of plant health and growth patterns.

Step 7: Embracing Automation and Data in Commercial Hydroponics

In the field of data-driven water quality optimization for commercial hydroponics, the integration of automation and data analytics is crucial for maximizing productivity and ensuring optimal growing conditions. Systems like GrowDirector 3 PRO represent a leap forward in this arena, offering advanced capabilities for monitoring and managing key aspects of hydroponic systems.

7.1. Implementing Hydroponic Water Management with GrowDirector 3 PRO

Automated Monitoring: Enhancing Growth Conditions

Automation technologies in hydroponic water management, like those found in GrowDirector 3 PRO, can continuously monitor and adjust critical parameters such as water pH, nutrient levels, and temperature. This system is designed to provide consistent and ideal growing conditions by automatically adjusting these crucial parameters. This ensures that plants are always in an environment tailored for their growth.

By maintaining such optimal conditions, GrowDirector 3 PRO have been known to significantly increase yields. The precision and consistency offered by these systems are key factors in enhancing productivity.

Discover our customers case studies here!

7.2. Data-Driven Water Quality Optimization for Commercial Hydroponics

The role of data analytics in optimizing hydroponic water management

- Tracking data-driven water quality optimization for commercial hydroponics: Data loggers, a feature often integrated into systems like GrowDirector 3 PRO, track water quality parameters over time. This capability is crucial for understanding the changing needs of plants throughout their growth cycles. Data play the crucial role of data analytics in optimizing hydroponic water management.

- Utilizing Data for Growth Optimization: By analyzing this data, growers can make more informed decisions to fine-tune their hydroponic systems, leading to improved plant health and yield. Systems equipped with data logging can provide valuable insights into the performance of the hydroponic setup, helping to identify trends and potential areas for improvement.

Step 8: Recycling and Water conservation strategies for hydroponic growers.

8.1. Why Sustainable hydroponic water management strategies for commercial growers is important?

Sustainable hydroponic water management strategies for commercial growers are critical due to the increasing demand for efficient use of water resources in agriculture. For commercial hydroponics, these strategies are not only about conserving a vital resource but also about enhancing the overall efficiency and profitability of the operation. Sustainable hydroponic water management strategies for commercial growers involve innovative practices like recycling water, using closed-loop systems, and implementing advanced irrigation techniques. These practices significantly reduce water consumption, which is particularly important in regions facing water scarcity.

Additionally, by minimizing water usage, growers can lower operational costs, making their businesses more sustainable both environmentally and economically. This approach aligns with the global shift towards more responsible and sustainable agricultural practices, ensuring that commercial hydroponic enterprises remain viable and productive in a world where water conservation is increasingly prioritized.

In commercial hydroponics, employing sustainable hydroponic water management strategies becomes essential for ensuring that this limited resource is utilized most efficiently. Such approaches not only help in conserving water, a crucial aspect in regions facing water shortages, but also significantly reduce operational costs, making commercial hydroponic ventures more economically viable. Furthermore, sustainable hydroponic water management strategies for commercial growers contribute to the overall health of the ecosystem by reducing water wastage and preventing the depletion of local water resources.

8.2. Implementing Water-Saving Technologies in Commercial Hydroponics

For commercial hydroponic growers, efficient water management is not just a cost-saving strategy; it’s an essential aspect of sustainable and productive farming. Here we delve into how technologies like moisture sensors, drip irrigation, and closed-loop systems are perfectly aligned with hydroponic practices and can significantly enhance water efficiency.

Moisture Sensors: Precision Irrigation in Hydroponic Water Management

Functionality and Benefits

Real-Time Moisture Monitoring. Moisture sensors provide crucial data on the water content in the growing medium, crucial for hydroponic systems that rely on balanced moisture levels for optimal plant growth.

Automating Irrigation. The data from these sensors can automate irrigation schedules, ensuring that plants receive precise water quantities, reducing both over and under-watering scenarios.

Practical Application Tips

- Strategic Sensor Placement: Install sensors at various points and depths in your hydroponic setup to get a comprehensive view of moisture distribution.

- Data Utilization: Regularly analyze sensor data to optimize irrigation schedules, ensuring efficient water use while maintaining plant health.

Drip Irrigation: Efficient Water Delivery in Hydroponics

Understanding Its Role in Hydroponic Water Management.

- Direct Water Delivery: Drip irrigation is highly effective in hydroponic systems that use inert media, providing water and nutrients directly to the root zone.

- Enhanced Efficiency: This method minimizes water wastage through evaporation and runoff, offering uniform hydration essential for consistent plant growth.

Setup and Maintenance Considerations

- Designing the Drip System: Ensure even coverage across all plants, considering emitter flow rates and plant spacing.

- Ongoing Maintenance: Keep emitters clean to prevent clogs and ensure uniform water distribution.

Closed-Loop Systems:

- Water and Nutrient Recirculation: Closed-loop systems epitomize the hydroponic principle of resource conservation, constantly recycling water and nutrients.

- Significant Water Savings: These systems can drastically reduce water usage, ideal for water-scarce regions, and promote sustainable nutrient usage.

Key Practices for Optimal Operation

- Regular Water Quality Checks: Test water in the reservoir frequently to maintain the right nutrient balance and pH levels.

- System Cleanliness: Prevent pathogen buildup and algae growth to ensure a healthy growing environment.

Moisture Sensors: Water Conservation Strategies for Hydroponic

What Are Moisture Sensors?

Moisture sensors are advanced devices that provide real-time data on the moisture content of the growing medium. They are typically inserted directly into the substrate or growing media.

How They Work

These sensors measure the volumetric water content and relay this information to a central system. Based on this data, the hydroponic system can precisely control the amount of water delivered to the plants, ensuring that they receive the optimal amount of moisture at all times.

Drip Irrigation: Maximizing Efficiency

Drip irrigation is a highly efficient watering method where water is delivered directly to the plant roots through a network of tubes, valves, and emitters. This system can be finely tuned to deliver water in controlled, precise amounts.

Benefits in Hydroponics

In hydroponic setups, drip irrigation is often used in conjunction with growing media like coco coir or rockwool. It allows for better oxygenation at the root zone and minimizes water and nutrient waste.

Closed-Loop Systems: The Ultimate in Water Conservation

The Concept of Closed-Loop Systems

Closed-loop hydroponic systems are designed to recycle and reuse water and nutrients. In these systems, water is continuously circulated, passing through the plant roots and then being filtered and returned to the system. By recirculating water and nutrients, closed-loop systems became the one of effective water conservation strategies for hydroponic growers. This method is particularly beneficial in areas where water is scarce, and it helps in maintaining a sustainable growing environment.

Environmental and Economic Advantages

These systems are particularly beneficial in areas where water is scarce. They maximize water use efficiency and significantly reduce the need for fresh water and nutrient inputs.

Conclusion: This guide is an answer for the question – how to optimize your hydroponic water system for maximum efficiency and yield? It combined detailed scientific principles, practical steps, and real-world case studies to provide a comprehensive approach to water management in commercial hydroponics. By understanding and implementing these strategies, commercial growers can ensure high yields, efficient operations, and sustainable practices. Regular monitoring, adaptation, and optimization based on these principles are key to the success and sustainability of your hydroponic ventures.