Choosing the Right Greenhouse Heater: A Comprehensive Guide for All Growers

As temperatures plummet and snow blankets the landscape, greenhouse owners face a critical question: how to keep their beloved plants safe and thriving through the harsh winter months. While greenhouses offer a controlled environment, they may not be enough to withstand the biting cold. This is where the powerful tool of a greenhouse heater comes in. This guide explores the world of choosing the right greenhouse heater, delves into practical tips for heating your greenhouse during winter, and unveils the different types of greenhouse heaters available, ensuring your plants flourish throughout the year.

Why Use a Greenhouse Heater?

A greenhouse heater is a great investment for any greenhouse owner, as it provides a consistent and controlled source of heat for your plants. This is especially important during the colder months when temperatures can drop below freezing. A greenhouse heater can help prevent frost damage and keep your plants healthy and thriving. It also allows you to extend your growing season, giving you the opportunity to grow plants that may not typically survive in your climate.

How where greenhouse heated before electricity?

Before the widespread availability of electricity, greenhouses relied on a variety of methods to maintain warmth for optimal plant growth. These methods varied in complexity and effectiveness, often depending on the climate, resources, and ingenuity of the grower. Here are some of the most common pre-electricity greenhouse heating techniques:

Direct Heat Sources:

- Fire pits and stoves: These provided direct heat and smoke, which could be beneficial for pest control but posed safety and air quality concerns.

- Flues and chimneys: Hot air from fireplaces or stoves could be channeled through flues and chimneys to heat the greenhouse indirectly.

- Animal shelters: The heat generated by animals like cows or horses could be harnessed to warm greenhouses through shared walls or ventilation systems.

Passive Heat Sources:

- Sunlight: Maximizing sunlight exposure through south-facing orientation and large windows was a key strategy.

- Hotbeds: Manure, straw, and other materials were composted to generate heat, which was then used to warm the soil and roots of plants.

- Thermal mass: Materials like rocks, bricks, and water were used to absorb heat during the day and release it slowly at night.

- Double glazing: Using two layers of glass with an air gap in between helped to trap heat and insulate the greenhouse.

Other Heating Methods:

- Fermentation: Fermenting materials like manure or straw released heat, which could be used to warm the greenhouse.

- Geothermal energy: Hot springs or naturally warm ground could be used to heat water or air for circulation in the greenhouse.

- Steam from industrial processes: Steam from factories or other industrial facilities could be used to heat greenhouses in some locations.

It’s important to note that pre-electricity greenhouse heating methods were often labor-intensive and required significant effort and knowledge to maintain consistent temperatures. The success of these methods depended heavily on the skill and resources of the grower.

With the advent of electricity, greenhouse heating became much more efficient and reliable. Today, a wide range of electric heaters and heating systems are available, offering growers greater control over temperature and creating more favorable conditions for plant growth.

Types of Greenhouse Heaters for Advanced Growers

Choosing the right greenhouse heater is crucial for maintaining optimal growing conditions and ensuring the success of your crops. Advanced growers need to consider several factors beyond just heating capacity, including fuel efficiency, emissions, safety, and environmental impact. Here’s a breakdown of the main types of greenhouse heaters:

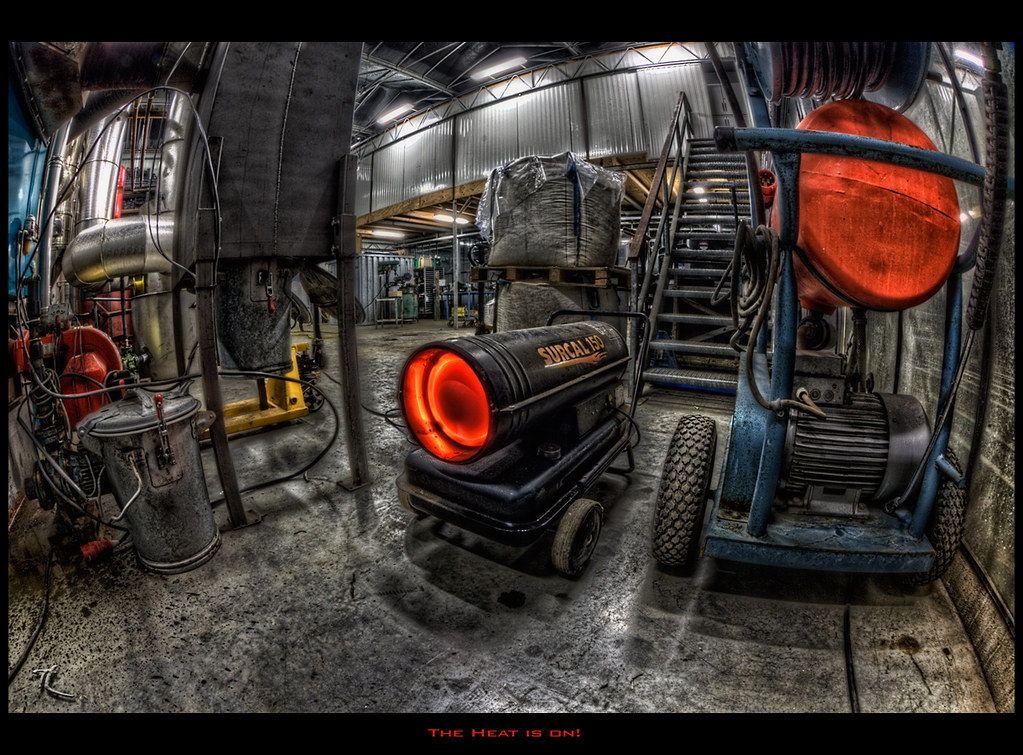

Combustion Heaters:

- Direct-fired heaters: These heaters directly burn fuel, such as propane or natural gas, to generate heat. They are generally the most efficient and cost-effective option, but they emit combustion gases that can harm plants and humans.

- High-efficiency models: These models utilize advanced technology to minimize emissions and improve fuel efficiency. Some even claim to be “plant-safe,” meaning they have met specific emission standards.

- Direct vent: These models vent combustion gases directly outside the greenhouse, eliminating the risk of harming plants.

- Indirect-fired heaters: These heaters burn fuel in a separate chamber, transferring the heat to air or water that is then circulated through the greenhouse. This method eliminates the risk of combustion gases entering the growing area but is less efficient and typically more expensive.

Electric Heaters:

- Fan heaters: These heaters use electric fans to blow warm air through the greenhouse. They are relatively inexpensive and easy to install but can be less efficient than other options.

- Radiant heaters: These heaters emit infrared radiation that directly warms objects, including plants and soil. They are energy-efficient and provide precise heat control but can be more expensive and have limited heat distribution.

Hydronic Heaters:

- Boilers: These heaters use hot water or steam to heat the greenhouse. They are efficient and provide even heat distribution but require a complex boiler system and piping infrastructure.

- Heat exchangers: These heaters transfer heat from a source, such as geothermal energy or waste heat from other processes, to the greenhouse water system. They are a sustainable and energy-efficient option but require specific infrastructure and may not be readily available in all locations.

Advanced Technologies:

- Condensing boilers: These boilers capture and utilize the latent heat in flue gases, further increasing their energy efficiency.

- Variable speed drives: These drives allow for precise control of fan speed, optimizing airflow and energy consumption.

- CO2 generators: These systems can be combined with combustion heaters to enrich the greenhouse atmosphere with CO2, potentially boosting plant growth.

| Type | Advantages | Disadvantages | Image |

|---|---|---|---|

| Direct-fired Heaters (Propane/Natural Gas) | * Most efficient and cost-effective

* High heating capacity * Easy to install and operate |

* Emit combustion gases that can harm plants and humans

* Potential safety hazards * Not suitable for enclosed spaces |

|

| High-efficiency direct-fired heaters | * Lower emissions than standard direct-fired models

* Improved fuel efficiency |

* Still emit combustion gases

* Higher initial cost |

|

| Direct vent heaters | * Eliminate the risk of combustion gases entering the growing area

* Safe for enclosed spaces |

* Less efficient than non-vented heaters

* Require additional installation costs for venting |

|

| Indirect-fired Heaters | * No combustion gases enter the growing area

* Safer for plants and humans * More efficient than direct-fired heaters in some cases |

* More complex and expensive to install

* Requires a separate boiler system and piping |

|

| Electric Fan Heaters | * Inexpensive and easy to install

* No emissions |

* Less efficient than other options

* Limited heat distribution |

|

| Electric Radiant Heaters | * Energy-efficient

* Precise heat control * No emissions |

* More expensive than fan heaters

* Limited heat distribution |

|

| Hydronic Heaters (Boilers) | * Efficient and provide even heat distribution

* Wide range of fuel options available |

* Complex and expensive to install

* Require a boiler system and piping |

|

| Heat Exchangers | * Sustainable and energy-efficient

* Utilize various heat sources |

* Require specific infrastructure

* May not be readily available in all locations |

Factors to Consider when Choosing a Greenhouse Heater:

- Fuel efficiency: Advanced growers should prioritize energy-efficient heating models to reduce operating costs and environmental impact.

- Emissions: Consider the type of fuel and emissions control technologies used by the heater to minimize the risk of harming plants and the environment.

- Safety: Ensure the heater is UL-listed and meets all relevant safety standards.

- Environmental impact: Look for heaters that use sustainable fuels or renewable energy sources.

- Heater size and capacity: Choose a heater with sufficient capacity to maintain the desired temperature in your greenhouse.

- Climate and growing needs: Tailor your heating system to the specific needs of your crops and the local climate.

- Budget: Consider your initial investment and long-term operating costs.

Additional Resources:

- Therma Grow Direct-Fired Heaters for Greenhouses: https://www.lbwhite.com/customer-care-center/heater-resources

- In Hot Pursuit Of Heating Trends For The Greenhouse: https://www.greenhousegrower.com/technology/

- Maintaining Energy-Efficient Greenhouse Heating During Cold Months:https://www.modinehvac.com/markets/greenhouses/

By carefully considering these factors and researching the available options, advanced growers can choose the most suitable greenhouse heating system for their specific needs.

Determining the right heater size for your greenhouse requires a multi-step process, considering:

1. Greenhouse size:

- Measure the total exterior surface area of your greenhouse in square feet. This includes walls, roof, and doors, but not the floor.

2. Heat loss factors:

- Identify the heat loss factor (U-factor) of your greenhouse materials. This value represents how readily heat escapes through the materials. Lower U-factors indicate better insulation.

- Common U-factors for greenhouse materials:

- Single-layer plastic: 1.5-2.0 BTU/(hrft²°F)

- Double-layer plastic: 0.75-1.0 BTU/(hrft²°F)

- Glass: 1.0-1.5 BTU/(hrft²°F)

3. Temperature difference:

- Calculate the desired temperature difference (ΔT) between the inside and outside of your greenhouse. This is typically the minimum temperature you want to maintain inside minus the average outdoor temperature during the coldest period.

4. Heater output:

- BTU (British Thermal Units) measure the heating capacity of a heater.

- Use the following formula to calculate the required heater output (BTUH): BTUH = Surface Area (sq ft) * U-factor (BTU/(hrft²°F)) * ΔT (°F)

5. Safety margin:

- Add a safety margin of 10-20% to the calculated BTUH to account for heat loss through ventilation, infiltration, and other factors.

Online Resources:

Several online tools can help you calculate the required heater size for your greenhouse:

- Greenhouse Heater Size Calculator: https://www.acfgreenhouses.com/greenhouse-heater-size-calculator.aspx

- Greenhouse Catalog Heater Calculator: https://www.greenhousecatalog.com/greenhouse-heating

- ACF Greenhouse Heaters & Heater Size + Cost to Heat Calculators: https://plantsbulbsseeds.com/best-small-greenhouse-heaters/

Tips for Using a Greenhouse Heater

To get the most out of your greenhouse heater, here are some tips to keep in mind:

- Place the heater in a central location in the greenhouse for even heat distribution.

- Use a thermostat to maintain a consistent temperature.

- Keep the heater away from any flammable materials.

- Regularly clean and maintain the heater to ensure its efficiency.

- Control and monitor your greenhouse temperature remotely using DryContactDirector or SocketDirector. Set custom schedules, receive alerts, and create the perfect climate for your plants to thrive!

Conclusion

A greenhouse heater is a valuable tool for any greenhouse owner, providing a controlled and consistent source of heat for your plants. Whether you choose a wood burning heater or an oil filled heater, it is important to consider the size of your greenhouse and your budget. With proper use and maintenance, a greenhouse heater can help you keep your plants warm and thriving throughout the winter months.