The VPD Blueprint: A Professional Guide to Climate Steering and Profitability

By Noam Dekel, Head Agronomist, GrowDirector

Last Updated: November 25, 2025

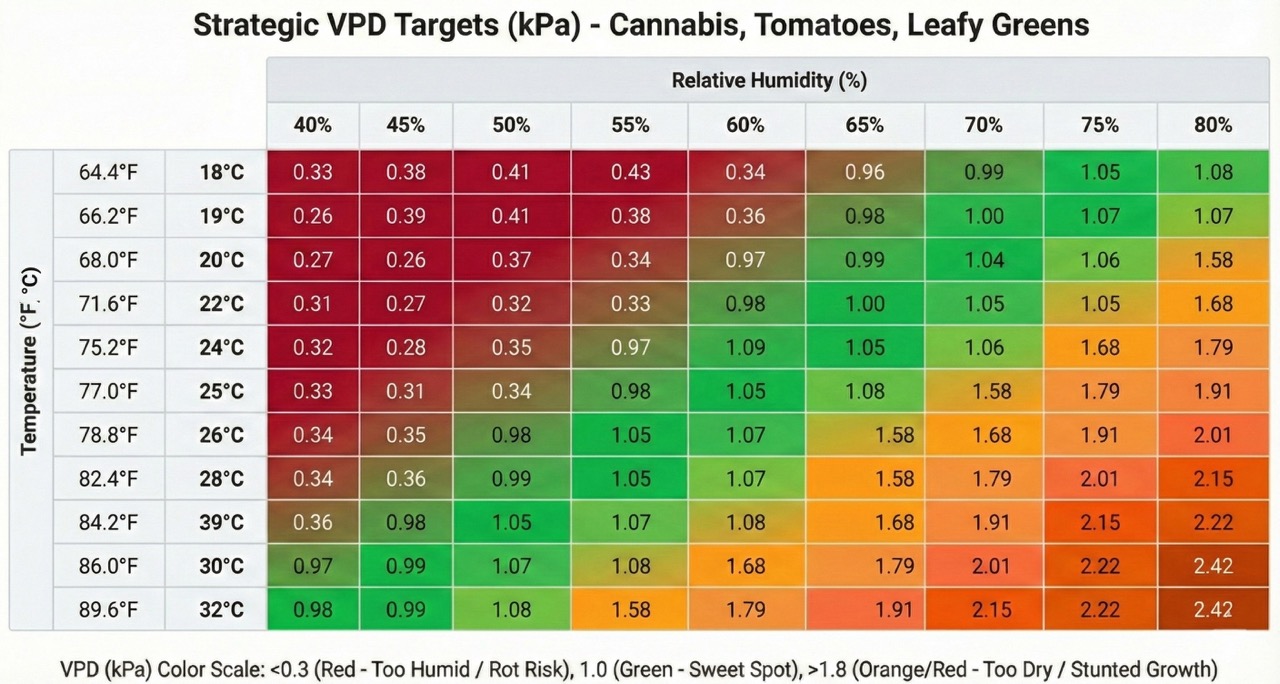

In the world of commercial Controlled Environment Agriculture (CEA), there’s a metric we’ve all been conditioned to chase: Relative Humidity (RH). For decades, it has been a cornerstone of environmental control. Yet, for any facility pursuing Operational Excellence, relying solely on RH (instead of VPD) is a critical limitation. It’s an incomplete and often misleading indicator of the actual atmospheric conditions your crop is experiencing.

The transition from intuition-based farming to data-driven biomanufacturing demands a more precise language and a more effective set of tools. The most powerful of these is Vapor Pressure Deficit (VPD). Understanding and controlling this parameter is not just an incremental improvement; it is a fundamental paradigm shift in climate management that directly impacts yield, quality, and the financial viability of your enterprise.

Why VPD is the Superior Metric for Commercial Operations

The core limitation of Relative Humidity is its dependency on temperature. A stable 70% RH reading can represent a low-stress environment at one temperature and a high-stress environment at another. An automation system programmed to this single variable can be blind to dramatic swings in the evaporative pressure on the plant.

VPD control resolves this ambiguity. As an absolute measure of pressure (typically in kPa), it quantifies the “drying potential” of the air. This is the primary force driving transpiration – the metabolic engine of your crop. For a commercial growers, managing Vapor Pressure Deficit means moving from reactive control to proactive, physiological steering. It ensures the repeatability and consistency required to scale production successfully.

Governing the Plant’s Metabolic Engine: The Central Role of Leaf VPD Control

Nearly every persistent cultivation challenge, from nuanced nutrient deficiencies to aggressive pathogen outbreaks, can often be traced back to a sub-optimal leaf VPD strategy.

I was recently brought in to consult for a multi-million dollar leafy greens operation battling persistent tipburn. The Head Grower was convinced it was a flaw in their fertigation recipe, having already invested heavily in adjusting their calcium supplementation. However, our sensor data revealed the true culprit: nighttime VPD was crashing to near-zero levels. Transpiration, the sole delivery mechanism for immobile nutrients like calcium, was stalling for hours. It didn’t matter how perfect the nutrient solution was; the delivery system was offline. By adjusting their dehumidification strategy to maintain a minimum nighttime Vapor Pressure Deficit, the tipburn was eliminated in the next crop cycle.

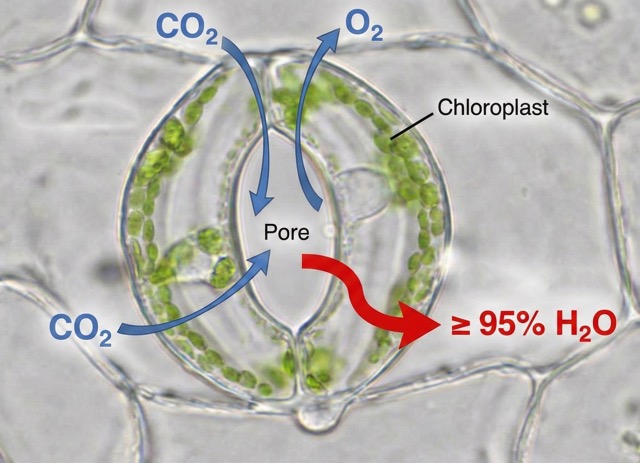

This is a classic example of how VPD governs the plant’s core functions by regulating stomata:

Optimal Vapor Pressure Deficit (e.g., 0.8 – 1.2 kPa): Stomata remain open, facilitating efficient gas exchange. The plant is actively transpiring, cooling itself, and uptaking CO₂. Your high-CapEx investments in lighting and CO₂ enrichment are generating maximum ROI.

- High VPD (> 1.6 kPa): The transpirational demand is too great. Stomata close to prevent desiccation. Photosynthesis effectively ceases, compromising yield potential and plant health.

- Low VPD (< 0.4 kPa): A stagnant, humid boundary layer forms on the leaf surface. Transpiration slows, hindering nutrient uptake, and creating the ideal microclimate for fungal pathogens like Botrytis to proliferate.

Implementation: A Framework for Strategic Crop Steering

An effective VPD strategy is dynamic and integrated with your overall cultivation plan, forming a cornerstone of modern Crop Steering. It is not a “set and forget” parameter.

A critical factor often overlooked is the difference between ambient air temperature and leaf surface temperature. Under a high Daily Light Integral (DLI), leaf temperature can be significantly higher than the surrounding air. This means the actual Leaf VPD (VPDleaf) is higher than what your climate computer calculates using only air temperature. I strongly advise any Head Grower to periodically validate their strategy using an infrared thermometer. The discrepancy can be surprising and is often the key to unlocking the next level of performance.

Based on best practices, here is a framework for stage-specific targets:

| Crop | Growth Stage | Strategic VPD Targets (kPa) | Agronomic Objective & Rationale |

| Cannabis | Propagation | 0.4 – 0.8 | Vegetative Steering: Minimize transpirational stress to promote adventitious root formation. |

| Vegetative | 0.8 – 1.2 | Drive vigorous growth and biomass accumulation through active nutrient uptake. | |

| Flowering | 1.2 – 1.6 | Generative Steering: Apply controlled stress to enhance secondary metabolite production and mitigate Botrytis risk in dense flower clusters. | |

| Tomatoes | Fruiting | 1.0 – 1.5 | Maintain strong Ca and K transport to developing fruit sets, preventing blossom-end rot. |

| Leafy Greens | All Stages | 0.7 – 0.9 | Ensure consistent nutrient delivery to prevent Ca-deficiency related tipburn and maintain turgor. |

Note: These ranges are a robust starting point. Final setpoints must be validated by daily Crop Registration and “walking the crop.”

Frequently Asked Questions for the Modern Grower

1. Is precise VPD control possible without a modern process computer?

While manual adjustments can influence VPD, achieving the stability and precision required for commercial-scale Operational Excellence is nearly impossible. A modern climate computer from a vendor like Argus, Priva, or Hoogendoorn is essential for executing a dynamic VPD strategy and ensuring Zero System Downtime.

2. How does VPD integrate with my precision irrigation strategy?

VPD is a primary driver of your irrigation schedule. On a high VPD day, transpiration increases, requiring more frequent, smaller irrigation “shot sizes” to maintain substrate moisture and prevent stressful drybacks. Conversely, on a low VPD day, irrigation frequency should be reduced.

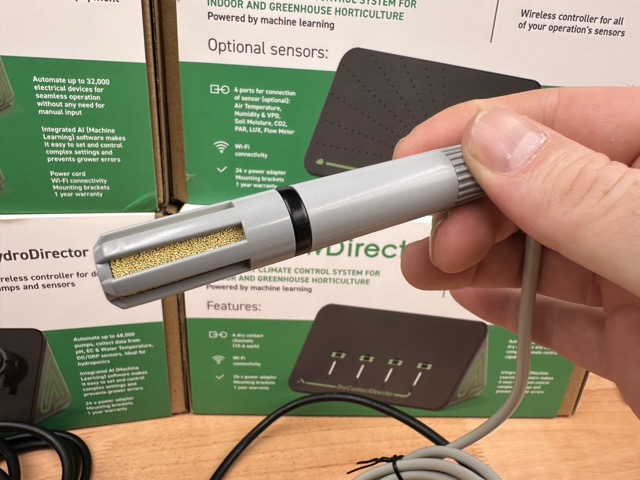

3. What is the optimal VPD sensor placement strategy for accurate data?

Sensors must be placed within aspirated boxes at canopy level. Data from a sensor near an HVAC unit or doorway is not representative of the microclimate your plants are experiencing. For large zones, multiple sensors are required to manage spatial variability.

Conclusion: From Climate Janitor to Plant Performance Manager

Mastering VPD marks a critical evolution in the grower’s role. It is the shift from a reactive to a proactive cultivation philosophy. It’s the difference between being a “climate janitor,” who constantly cleans up environmental problems, and a true plant performance manager, who uses precise atmospheric control to steer the crop toward predictable, high-quality outcomes. This is the essence of modern, data-driven biomanufacturing.

About the Author:

Noam Dekel is the Head Agronomist of GrowDirector, a company at the forefront of developing automated cultivation control systems. His work is centered on the critical intersection of plant science and systems engineering. He works directly with commercial growers worldwide to implement data-driven strategies to solve complex cultivation challenges, ultimately enhancing yield, ensuring crop consistency, and maximizing operational profitability.

READ MORE: