Soil Moisture Sensors and Meters: A Practical Guide for Commercial Greenhouses in the 2025 Growing Season

In the competitive world of commercial greenhouse cultivation, optimizing irrigation strategies is paramount to achieving maximum yields and maintaining plant health while minimizing water and fertilizer usage. Soil moisture sensors and meters have emerged as indispensable tools for growers, providing real-time data on substrate water content and enabling precise irrigation management. These sensors can also be used to control fertilizer application (fertigation), allowing growers to optimize both water and nutrient delivery to plants . This comprehensive guide delves into the practical aspects of soil humidity sensor usage, offering valuable insights for commercial greenhouse growers in the 2025 growing season.

Trends and Technologies for the 2025 Growing Season

The field of soil moisture sensing is constantly evolving, with new technologies and trends emerging to further enhance irrigation management in commercial greenhouses . Here are some key developments to watch for in the 2025 growing season:

- Wireless sensors: Wireless soil moisture sensor is becoming increasingly popular, offering greater flexibility and ease of installation . This reduces the labor costs associated with installation and maintenance.

- Data integration: Soil moisture data is being integrated with other environmental data, such as temperature, humidity, and light levels, to provide a more holistic view of growing conditions . This allows growers to fine-tune their irrigation strategies based on a comprehensive understanding of the greenhouse environment.

- Artificial intelligence (AI): AI is being used to analyze soil moisture data and provide growers with more precise irrigation recommendations . AI-powered irrigation systems can learn from historical data and adapt to changing conditions, optimizing water and fertilizer usage for each specific crop.

- Remote sensing: Remote sensing technologies, such as drones and satellites, are being used to map soil moisture variability across large greenhouse operations . This allows growers to identify areas with different water requirements and adjust their irrigation accordingly.

Understanding Soil Moisture Sensors and Meters

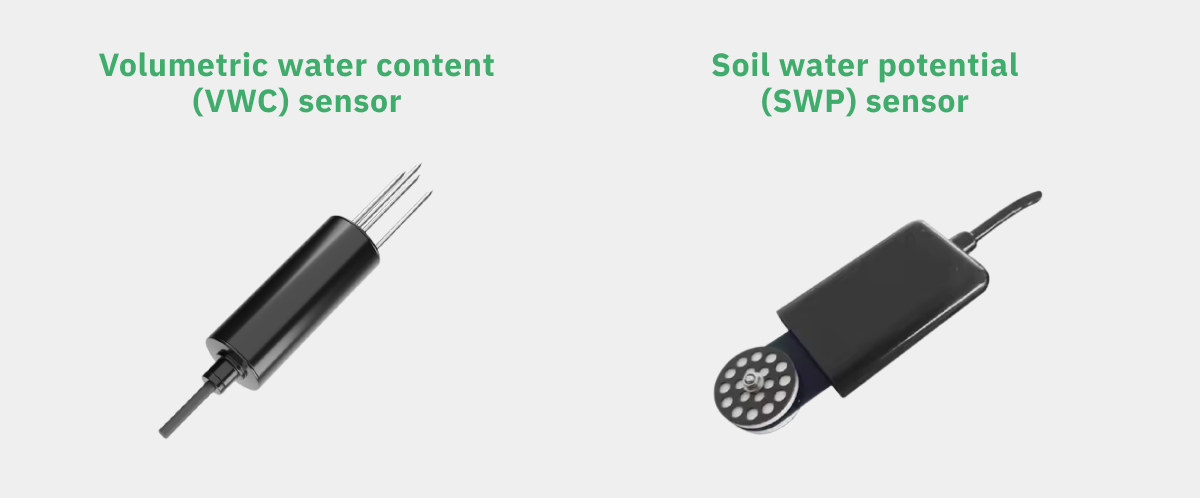

Soil moisture sensors and meters are devices that measure the amount of water present in the growing substrate. This information helps growers determine when and how much to irrigate, ensuring that plants receive the optimal amount of water for healthy growth and development. There are two main types of soil moisture sensors and meters:

- Volumetric water content (VWC) sensors: These sensors measure the volume of water present in the substrate relative to the volume of the substrate. They are commonly used in commercial greenhouses and provide accurate readings for a variety of growing media.

- Soil water potential (SWP) sensors: These sensors measure the tension with which water is held in the substrate. This tension, also known as matric potential, reflects the force that plants need to exert to extract water from the soil . Soil water potential is a critical factor in determining plant-available water, as plants can only readily access water that is held with a low tension.

Understanding different soil moisture levels and their implications for plant growth is crucial for effective irrigation management. For example, if the soil water potential is too high (i.e., the water is held too tightly), plants may not be able to extract the moisture they need, leading to stress and reduced growth. Conversely, if the soil water potential is too low (i.e., the water is held too loosely), it may drain away too quickly, leaving the roots dry.

Selecting the Right Soil Moisture Sensor or Meter

Choosing the appropriate soil moisture sensor or meter is crucial for effective irrigation management. Consider the following factors when making your selection:

- Accuracy: The sensor should provide accurate and reliable readings for the specific type of growing media used in your greenhouse.

- Durability: The sensor should be able to withstand the harsh conditions of a greenhouse environment, including temperature fluctuations, humidity, and potential physical damage.

- Ease of use: The sensor should be easy to install, calibrate, and maintain.

- Cost: Consider the initial cost of the sensor, as well as any ongoing maintenance or replacement costs.

- Integration: Ensure that the sensor is compatible with your existing irrigation system and any other monitoring or control systems you may have in place.

- Number of sensors: The number of sensors needed for a greenhouse depends on factors like the size of the greenhouse, the types of crops being grown, and the variability of soil conditions . For example, a larger greenhouse with diverse crops and varying soil types may require more sensors to provide a comprehensive picture of soil moisture levels. Different crops have different water requirements, and sensors should be placed strategically to capture these variations.

Soil Moisture Sensor and Meter Manufacturers

Several manufacturers offer soil moisture sensors and meters suitable for commercial greenhouse applications. Here are a few examples:

- Delmhorst Instrument Co.: Delmhorst is a leading manufacturer of moisture measurement instruments, including soil moisture sensors and meters. They offer a wide range of sensors for various applications, including agriculture, forestry, and research.

- Spectrum Technologies, Inc.: Spectrum Technologies provides a variety of sensors and monitoring solutions for agriculture, including soil moisture sensors and meters. Their sensors are designed for use in various settings, including greenhouses, fields, and turfgrass.

- METER Group, Inc. USA: METER Group offers a range of soil moisture sensors and meters with research-grade accuracy. Their sensors are designed to be insensitive to salts, temperature gradients, and soil texture, making them suitable for a variety of greenhouse environments.

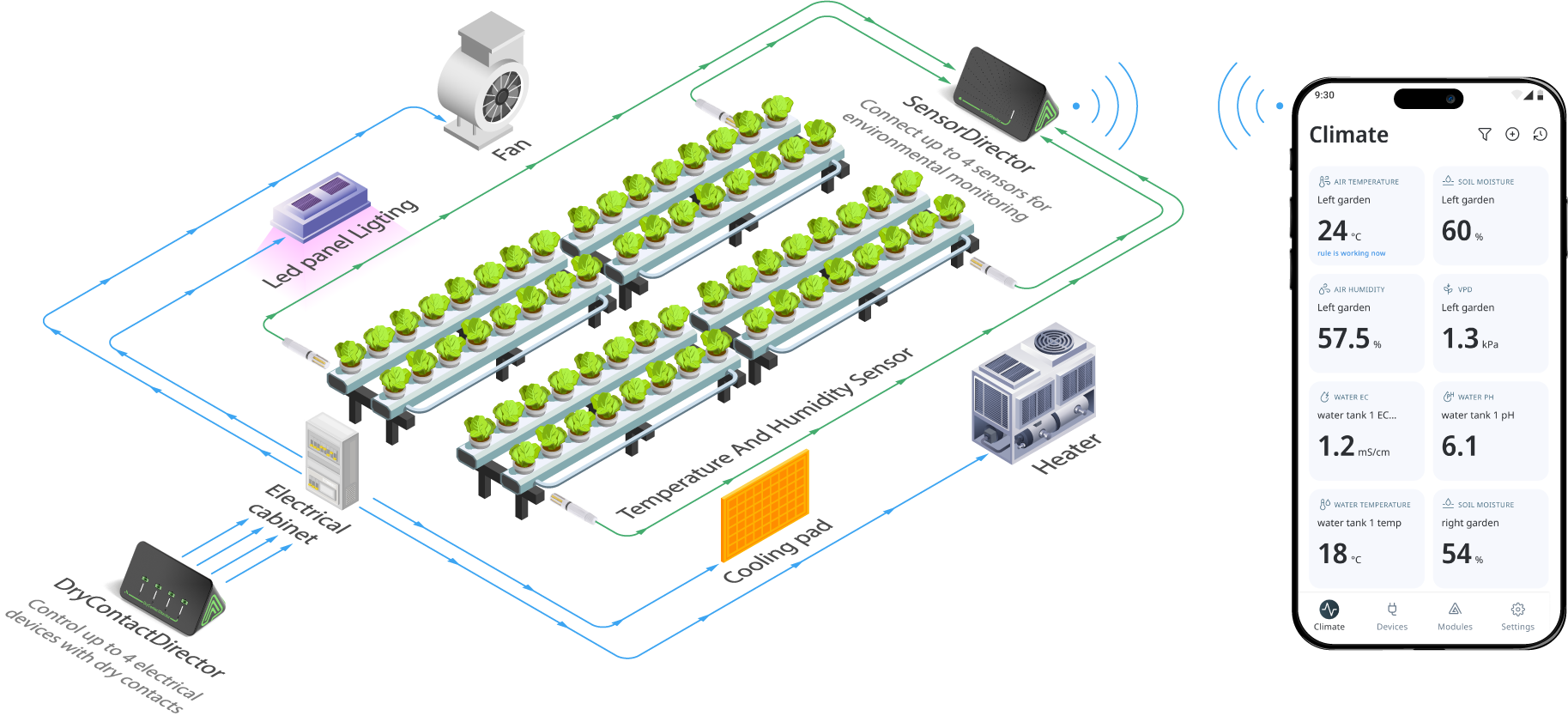

- GrowDirector: GrowDirector offers the GrowDirector 3 Pro system, an AI-powered environmental control system that integrates with various sensors, including soil moisture sensors, soil moisture meters, and moisture meters for plants. The GrowDirector Soil Kit provides a comprehensive solution for soil cultivation management, offering real-time insights and automated control for optimized irrigation and improved crop yields.

GrowDirector’s Soil Kit includes:

- SensorDirector: Collects data from various sensors, including soil moisture sensors, air temperature and humidity sensors, and more.

- DryContactDirector: Controls irrigation systems, ventilation fans, and other devices based on real-time data.

- Soil Moisture Sensor: Provides accurate and reliable soil moisture readings.

- Air Temperature, Humidity & VPD Sensor: Monitors key environmental factors.

With its AI-powered software and user-friendly app, GrowDirector simplifies greenhouse management and helps growers achieve optimal growing conditions.

- SoilSense: SoilSense provides soil moisture sensors and meters designed for use in orchards, vegetable farms, and landscaping. Their sensors are integrated with a dashboard and data logger for easy monitoring and analysis.

- Sentek Technologies: Sentek specializes in soil moisture monitoring technologies. They offer sensors that provide high-resolution data and can detect even small changes in moisture levels.

Installing Soil Moisture Sensors and Meters

Proper installation is essential for accurate and reliable soil moisture readings. Follow these guidelines for optimal sensor placement:

- Representative area: Choose a location that represents the average soil conditions and crop growth patterns in your greenhouse. Avoid areas with excessive vigor , poor drainage , or unusual soil depth.

- Avoid obstacles: Do not place sensors near structures, impervious surfaces, or other obstacles that could interfere with readings . For example, avoid placing a soil moisture indicator near a metal support beam or a concrete walkway.

- Soil contact: Ensure good contact between the sensor and the surrounding soil. Avoid air pockets, which can lead to inaccurate readings . When installing a soil humidity sensor, make sure the probes are fully inserted into the soil and that there are no gaps between the probes and the surrounding soil.

- Depth: Place the sensor at a depth that corresponds to the active root zone of your plants. For larger plants or those with deeper root systems, consider using multiple sensors at different depths . For example, you might use a ground moisture meter at a depth of 6 inches for shallow-rooted plants and another at 12 inches for deeper-rooted plants.

- Wetting and drying: Before installing the sensor, follow the manufacturer’s recommendations for wetting and drying the sensor to ensure optimal performance . This may involve soaking the sensor in water for a specific period or allowing it to air dry.

- Threshold: The threshold is the point at which the sensor triggers an irrigation event. This threshold can be adjusted based on the specific needs of the crops . For example, crops that are more sensitive to drought stress may require a higher threshold to ensure they receive adequate water.

Placement Strategies for Soil Moisture Sensors

- In-ground: For in-ground installations, place sensors in a grid pattern to get a comprehensive view of soil moisture across the greenhouse . The number of sensors needed will depend on the size of the greenhouse and the variability of soil conditions.

- Pots and grow bags: In pots and grow bags, place one sensor per container, ensuring the probe is in contact with the root zone. For larger containers or deeper-rooted plants, consider using multiple sensors at different depths.

- Drip irrigation: When using drip irrigation, place the sensor near the dripper to ensure accurate readings of the moisture level in the root zone .

By following these guidelines, you can ensure that your soil moisture sensors are installed correctly and provide accurate and reliable data for optimal irrigation management.

How Many Soil Moisture Sensors Do You Need?

The number of soil moisture sensors you need depends on several factors, including:

- Greenhouse Size and Layout: Larger greenhouses may require more sensors to accurately monitor different zones or areas with varying soil conditions.

- Plant Type and Growth Stage: Different plants have different water requirements, and their needs may change throughout their life cycle.

- Irrigation System: If you have a zone-based irrigation system, you may need a sensor for each zone to optimize water distribution.

- Desired Level of Precision: For precise control, more sensors can provide granular data on soil moisture levels.

General Recommendations:

- Small to Medium-Sized Greenhouses: Start with 2-4 sensors to monitor key areas.

- Large Commercial Greenhouses: Consider using 10 or more sensors to ensure comprehensive coverage.

- For High-Value Crops: Invest in additional sensors for precise monitoring and control.

Remember: The key is to strike a balance between cost and precision. By strategically placing sensors, you can effectively monitor your greenhouse environment and optimize water usage.

Maintaining Soil Humidity Meter

Regular maintenance is crucial for ensuring the longevity and accuracy of your soil moisture sensors and meters. Follow these maintenance practices:

- Cleaning: Clean the sensor surface regularly to remove any accumulated debris or residue . This is especially important for sensors with exposed probes, as dirt and debris can interfere with the sensor’s readings.

- Calibration: Calibrate the sensor periodically to ensure accurate readings . Calibration methods vary depending on the sensor type, but they often involve comparing sensor readings to gravimetric soil moisture measurements.

- Inspection: Inspect the sensor for any signs of damage or wear and tear. Replace damaged sensors promptly . For example, if the probes of a moisture detector for plants are bent or broken, the sensor may need to be replaced.

- Storage: If you need to remove the sensor from the soil for an extended period, store it according to the manufacturer’s instructions . This may involve cleaning the sensor, drying it thoroughly, and storing it in a cool, dry place.

Troubleshooting Common Watering Sensor Problems

Soil moisture sensors and meters can sometimes encounter problems that affect their performance. Here are some common issues and troubleshooting tips:

| Problem | Possible Cause | Solution |

|---|---|---|

| Electrical problems | Poor power connections or circuit damage | Check the power supply and circuit connections. Ensure that the sensor is receiving power and that the wires are intact. |

| Water accumulation | Long-term use in a damp environment | Clean the sensor and ensure proper waterproofing measures are in place. Use waterproof connectors or sealant tape to protect the sensor and connection parts from moisture ingress. |

| Physical damage | Crushed, bumped, or exposed to harsh environments | Inspect the sensor for any physical damage, such as cracks or broken probes. Replace damaged sensors as needed. |

| Inconsistent readings | Air pockets, soil disturbance, or preferential flow paths | Ensure good soil contact with the sensor and avoid air pockets. Minimize soil disturbance around the sensor. |

Data Logging and AI Analysis with GrowDirector

Data logging is a crucial aspect of maximizing the benefits of soil moisture sensors and meters. By logging sensor data over time, growers can track trends, identify potential problems, and optimize irrigation strategies . For example, data logging can help growers determine the optimal irrigation frequency and amount for different crops and growing conditions. It can also help identify areas where water is being wasted or where plants are not receiving enough moisture.

GrowDirector’s AI-powered controllers and software take data logging and analysis to the next level. The GrowDirector system can automatically collect data from various sensors, including soil moisture sensors, soil moisture meters, moisture meters for plants, and other environmental sensors . This data is then analyzed by GrowDirector’s AI algorithms to provide growers with real-time insights and actionable recommendations.

For example, GrowDirector AI can:

- Predict and prevent potential issues like fungal diseases, weather disruptions, and irrigation problems.

- Optimize your greenhouse environment for each growth stage, maximizing yields and plant health.

- Provide early warnings of possible fungal outbreaks.

- Adapt to weather changes with weather-based predictions and automatic adjustments to your greenhouse environment.

- By integrating data logging and AI analysis, GrowDirector empowers commercial growers to make more informed decisions, optimize their irrigation strategies, and achieve better results.

Benefits of Using Soil Moisture Meter

Using soil moisture sensors and meters offers several advantages over traditional irrigation methods:

- Improved water use efficiency: Sensors help prevent over- and underwatering, leading to more efficient water use and reduced costs.

- Reduced labor costs: Automated irrigation systems based on soil moisture sensors can reduce the need for manual irrigation, freeing up labor for other tasks.

- Enhanced plant health: By providing optimal water levels, sensors promote healthy plant growth and reduce the risk of diseases associated with over- or underwatering.

- Increased crop yields and quality: Soil moisture sensors can help optimize water and nutrient delivery to plants, leading to improved crop yields and quality.

Water Sensor Challenges and Limitations

While soil humidity meter offer significant benefits, it’s important to be aware of potential challenges and limitations:

- Sensor accuracy: The accuracy of soil moisture meter can be affected by factors such as soil type, temperature, and salinity.

- Cost: Soil moisture meter can be expensive, especially for large greenhouse operations.

- Installation and maintenance: Proper installation and maintenance are crucial for accurate and reliable sensor performance.

Frequently Asked Questions About Ground Moisture Meter

Here are some frequently asked questions about watering sensor:

- Where should we avoid placing soil moisture sensors? Avoid areas with excessive vigor, poor drainage, unusual soil depth, or obstacles that could interfere with readings.

- How much area can a soil moisture sensor or meter cover? Most sensors can cover an area of 1 to 2 acres, but this can vary depending on the sensor and environmental factors.

- What is the difference between a soil moisture sensor and a rain sensor? Soil moisture sensors measure the water content in the soil, while rain sensors detect rainfall.

- How do I know if my soil moisture sensor or meter is working? You can test the sensor by placing it in dry and wet soil and observing the readings.

- What depth do you measure soil moisture? The depth depends on the root zone of the plants. For most plants, measuring at a depth of 6-8 inches is sufficient.

- How do you calibrate a soil moisture sensor or meter? Calibration methods vary depending on the sensor, but they often involve comparing sensor readings to gravimetric soil moisture measurements.

How many soil moisture sensors do I need?

It’s not a one-size-fits-all answer. The number of soil moisture sensors you need depends on a few things:

- Greenhouse size: Obviously, a bigger greenhouse needs more sensors. I started with one sensor per acre, but I found that wasn’t enough. Now I use about 2-3 sensors per acre, and that gives me a much better picture of what’s going on in my soil.

- Crop type: Different crops have different water needs. Some crops, like tomatoes, are pretty thirsty, while others, like lettuce, need less water. If you’re growing a variety of crops, you’ll need more sensors to make sure each crop is getting the right amount of water.

- Soil variability: Soil conditions can vary a lot, even within a single greenhouse. You might have sandy soil in one area and clay soil in another. This can affect how quickly the soil dries out, so you’ll need more sensors in areas with more variability.

- Irrigation system: If you have a complex irrigation system with multiple zones, you’ll need more sensors to monitor each zone effectively. For example, I have one sensor per irrigation zone in my greenhouse .

Here’s a practical example:

Let’s say you have a 1-acre greenhouse growing tomatoes. Tomatoes have a deep root system, so you’ll want to monitor the soil moisture at different depths. You might start with three soil moisture sensors: one at 6 inches, one at 12 inches, and one at 18 inches. This will give you a good idea of how the soil moisture is changing throughout the root zone.

If you have a larger greenhouse or more variability in your soil conditions, you’ll need more sensors. You can also use data logging and analysis to help you determine the optimal number of sensors for your specific needs.

Here are some other things to consider:

- Terrain: If your greenhouse has variations in altitude, you’ll need more sensors to cover the different moisture levels . Higher areas tend to be drier, while lower areas are wetter.

- Sensor technology: Some soil moisture sensors have a wider range than others. For example, some sensors can cover an area of 1 to 2 acres , while others have a smaller range.

- Budget: Soil moisture sensors can be expensive, so you’ll need to factor that into your decision. But trust me, they’re worth the investment. They can save you a lot of money on water and fertilizer in the long run.

Ultimately, the best way to determine how many soil moisture sensors you need is to experiment and see what works best for your greenhouse. Start with a few sensors and add more as needed. And don’t forget to monitor your data and make adjustments as necessary.

Conclusion

Soil moisture sensors and meters are revolutionizing irrigation management in commercial greenhouses. By providing real-time data on substrate water content, these sensors enable growers to optimize irrigation strategies, leading to improved water use efficiency, reduced labor costs, and enhanced plant health . Proper sensor selection, installation, and maintenance are crucial for accurate and reliable performance . New technologies, such as wireless sensors, AI-powered irrigation systems, and remote sensing, are further enhancing the capabilities of soil moisture sensors and shaping the future of greenhouse irrigation . By embracing these advancements, commercial greenhouse growers can maximize yields, improve crop quality, and contribute to a more sustainable future.

Consult with a GrowDirector Expert:

For personalized recommendations, consult with our team of experts. They can assess your specific needs and recommend the optimal number of sensors for your greenhouse.

By leveraging the power of data and AI-driven insights, you can achieve optimal plant growth and maximize your yields.