Guide 2024: Selecting and Buying a Commercial Greenhouse

After 13 years as an agronomist, I’ve seen plenty of commercial greenhouse construction. Some succeed, some struggle. That’s why I’m excited to share my recent conversation with Patrick Gelineau, the General Manager of DeCloet Greenhouse Manufacturing. They are tackling things with a new outlook.

The excitement of expanding your operation is often tempered by a host of questions:

- “How much is this ultimately going to cost me?”

- “Should I build it myself or buy a commercial greenhouse kit?”

- “What about keeping the energy bills under control?”

- “Where to buy best greenhouse?”

- “How to select a commercial greenhouse?”

…and many more.

Where to buy best greenhouse?

Finding the right commercial greenhouse involves more than just choosing a style and size. You also need to find a reputable supplier that offers quality products and excellent customer service. Here’s a breakdown of where to buy the best greenhouses, based on my experience and feedback from fellow growers:

1. Local Commercial Greenhouse Suppliers:

- Pros: Personalized service, expert advice, potential for installation support, and the opportunity to see greenhouses firsthand.

- Cons: May have limited selection or higher prices compared to online retailers.

- Tip: Search online for “greenhouse suppliers near me” or visit local nurseries and garden centers.

2. Online Retailers:

- Pros: Wide selection, competitive commercial greenhouse cost, convenient shopping experience, and access to customer reviews.

- Cons: May require more research to ensure quality and compatibility, potential for shipping delays or damage.

- Tip: Check reputable online retailers like Amazon, Home Depot, Lowe’s, and Greenhouse Megastore.

3. Commercial Greenhouse Manufacturers:

- Pros: Direct access to manufacturer expertise, potential for customization options, and often better warranties.

- Cons: May have higher prices or limited availability compared to retailers.

- Tip: Research leading commercial greenhouse manufacturers like DeCloet, Riga, Juliana, and Palram. Many offer online ordering or have a network of authorized dealers.

4. Specialized Greenhouse Websites:

- Pros: Curated selection of high-quality commercial greenhouses, expert reviews and comparisons, and often helpful buying guides.

- Cons: May have limited selection or higher prices compared to larger retailers.

- Tip: Explore websites like Greenhouse Review, Planet Greenhouse, and Mulberry Greenhouses.

The Greenhouse Dream

I wanted to learn more about these issues. So, I started a journey to DeCloet Greenhouses in Canada. DeCloet was established in 1986 and have been selling greenhouses and greenhouses solutions to both the US and Canadian Market since then.

This company is known for their greenhouse innovation. I was lucky enough to sit down with Patrick, a seasoned expert at DeCloet Greenhouses. Over a steaming cup of coffee, we dove deep into the nitty-gritty of greenhouse investments.

I started with the big one: cost. “Patrick,” I asked, “what are the main things driving up the price of greenhouses these days?”

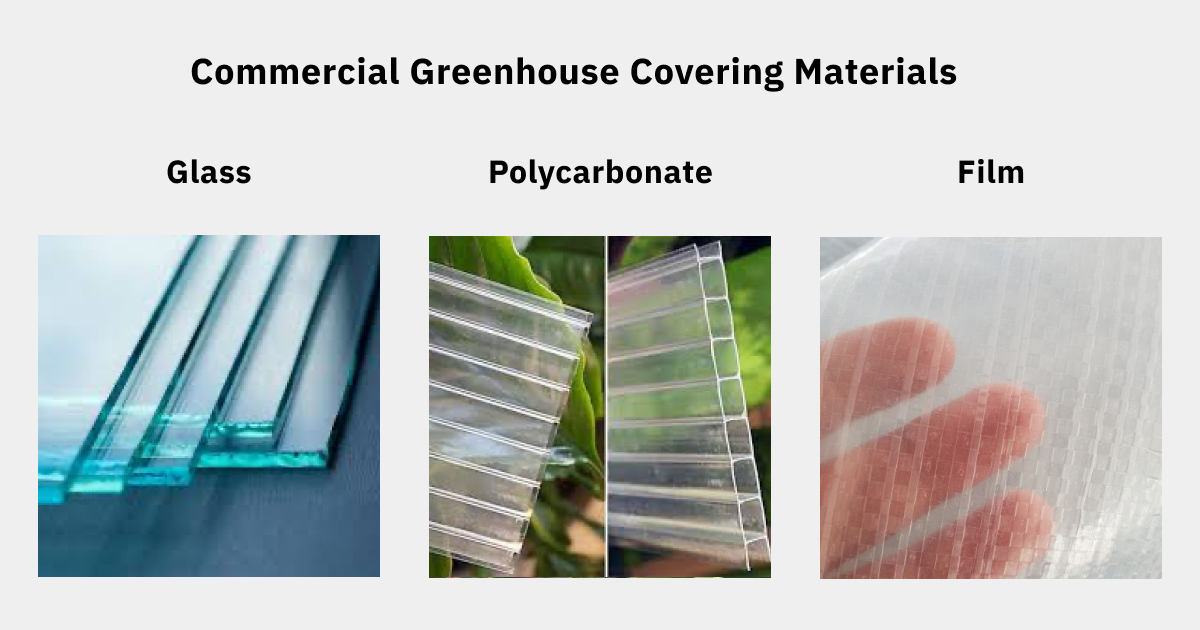

He didn’t miss a beat. “It’s a mix of things, Noam. Size and design are major factors. The bigger and fancier you go, the more it’ll cost. Materials matter too – glass lets in tons of light, but it’s pricey. Polycarbonate is a good middle ground, and film is the budget option. Costs for labour versus automation is always in the forefront of our clients concerns“

We talked about many topics, including environmental control systems and the hidden costs of labor and permits. Patrick even shared some insider tips on choosing the right location for your greenhouse.

How to choose commercial greenhouse?

As we talked, it became clear that DeCloet understands the challenges growers face.

Patrick proudly explained, “We design our commercial greenhouse construction with growers in mind. Take our GrowMax series, for example. It’s perfect for large operations that need to maximize yield, yet cannot afford Gutter Connect Solutions. Higher sidewall options allow you to grow using benches and even have a shade system due to our truss design.

The truss design provides you with plenty of space for hanging baskets, and it features a tough construction to handle whatever Mother Nature throws at it.”

He said, “We know time is money. That’s why our Gutter Connect and Freestanding commercial greenhouses are easy to install yourself.” We even include step-by-step instructions. But if you’d rather leave it to the pros, we’ve got you covered there too.” Often, the cost of the structure is known – but the time and money required to assemble is critical as you have the most risk associated with the installation. We offer solutions to minimize the total, not simply transfer the risk to the assembly stage.

I was impressed. DeCloet’s focus on affordability, ease of installation, and flexibility was evident. They’re clearly committed to helping growers succeed.

I asked Patrick if it’s cheaper to build a commercial greenhouse yourself or to buy a kit, as many people often wonder about this.

Patrick: “That’s a classic. I hear it all the time too. Generally speaking, a commercial greenhouse kit is going to be easier on the wallet, especially if you’re starting small or just dipping your toes in the water. You get all the parts ready to go, and assembly is a whole lot simpler. Saves you time and money.”

Cropmaster – 34′ / 35′ width

“For instance,” he continued, “our Freestanding greenhouses start at around $5 per square foot. That’s a pretty attractive price point for a turnkey solution. Of course, if you have specific needs or a larger operation, a custom-built greenhouse might be the way to go. But it’s essential to weigh the costs and benefits carefully.”

Commercial Greenhouse Covering Materials

Choosing the right materials for your commercial greenhouse is very important. This decision affects both your crop’s success and your profits.

| Feature | Glass | Polycarbonate | Film |

| Light Transmission | Highest, excellent for plant growth. Low-iron options enhance clarity. | Good balance of light and durability. Multi-wall options improve insulation. |

Lowest; multi-layer films improve durability and light diffusion.

|

| Durability | Long-lasting (decades) but susceptible to breakage from hail or snow. | Excellent impact resistance, withstands harsh weather. May scratch or yellow over time. |

Shortest lifespan, needs frequent replacement (every few years).

|

| Climate | Ideal for various climates, especially with double-glazing. | Suitable for various climates; multi-wall for cold climates. |

Best for mild climates; may require extra ventilation or cooling in hot climates.

|

| Energy Efficiency | Good with double-glazing or low-E coatings. | Good, especially multi-wall options. |

Lowest; consider energy-efficient films.

|

| Cost | Highest initial investment. | Moderate initial investment. |

Lowest initial investment.

|

| Maintenance | Low maintenance, but repairs can be costly. | Moderate maintenance; potential for scratches and yellowing. |

High maintenance due to frequent replacement.

|

| Emerging Trends | Low-iron glass, smart glazing (electrochromic) | – |

ETFE film, recycled materials

|

Remember:

- Consult with Experts: Seek advice from experienced greenhouse consultants or engineers to help you select the best materials for your specific needs and climate.

- Consider Your Crops: Different crops have varying light and temperature requirements. Choose materials that support your specific crop needs.

- Think Long-Term: Balance upfront costs with long-term durability, maintenance, and potential energy savings.

Beyond Construction: Operational Expenses and Location Choice

Patrick emphasized the importance of energy efficiency and smart technology. We talked about the daily challenges of managing a greenhouse.

“Running a greenhouse isn’t just about the building itself,” he explained. “Heating, cooling, ventilation, irrigation – it all adds up. That’s why we design our greenhouses to be as energy-efficient as possible and recommend tools like GrowDirector to help growers fine-tune their environment and save on energy costs.”

How Commercial Greenhouses Work: A Simplified Explanation

Commercial greenhouses operate on the principle of creating a controlled environment that optimizes plant growth. They essentially trap solar radiation, creating a warmer microclimate inside even during colder months. Here’s the breakdown:

Structure:

- Frame & Covering: The frame provides support, while the transparent covering (glass, polycarbonate, or film) allows sunlight in while trapping heat.

- Ventilation: Vents and fans regulate temperature and humidity by allowing air exchange.

- Heating & Cooling: Systems like heaters, boilers, or evaporative cooling pads maintain optimal temperatures year-round.

- Irrigation & Fertigation: Drip irrigation or hydroponic systems deliver water and nutrients directly to plant roots.

- Lighting: Supplemental lighting, often LEDs, extends the growing season or provides consistent light levels.

- Environmental Controls: Sensors and computerized systems monitor and adjust temperature, hufmidity, CO2 levels, and other factors for ideal growing conditions. Learn more about commercial greenhouse automation here!

Running Commercial Greenhouse Processes:

- Crop Selection: Growers choose crops based on market demand, growing season, and suitability for the greenhouse environment.

- Planting & Propagation: Seeds or seedlings are started in trays or directly in the growing medium.

- Environmental Management: The greenhouse’s systems maintain optimal temperature, humidity, light, and CO2 levels.

- Nutrient Management: Fertilizers are delivered through the irrigation system to provide essential nutrients.

- Pest & Disease Control: Integrated pest management (IPM) strategies are employed to minimize the use of chemicals.

- Harvesting & Post-Harvest Handling: Crops are harvested at their peak maturity and processed for sale or distribution.

Commercial greenhouses are sophisticated systems that leverage technology and controlled environments to maximize crop yields and extend growing seasons. By understanding how these systems work, growers can make informed decisions about their operations and investments.

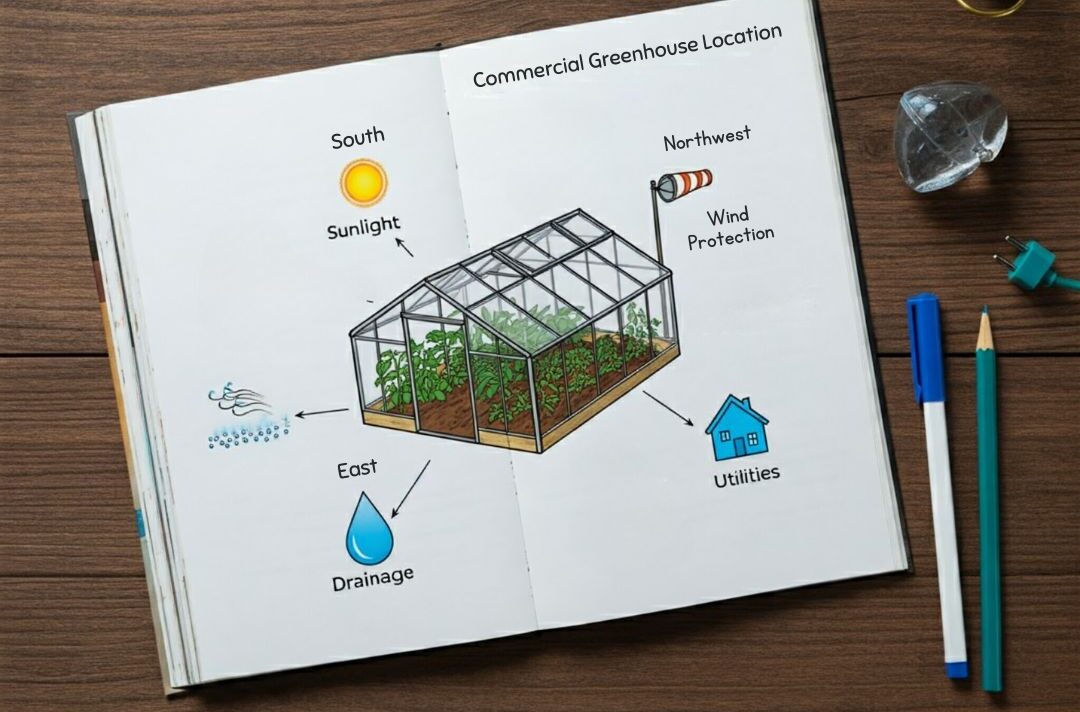

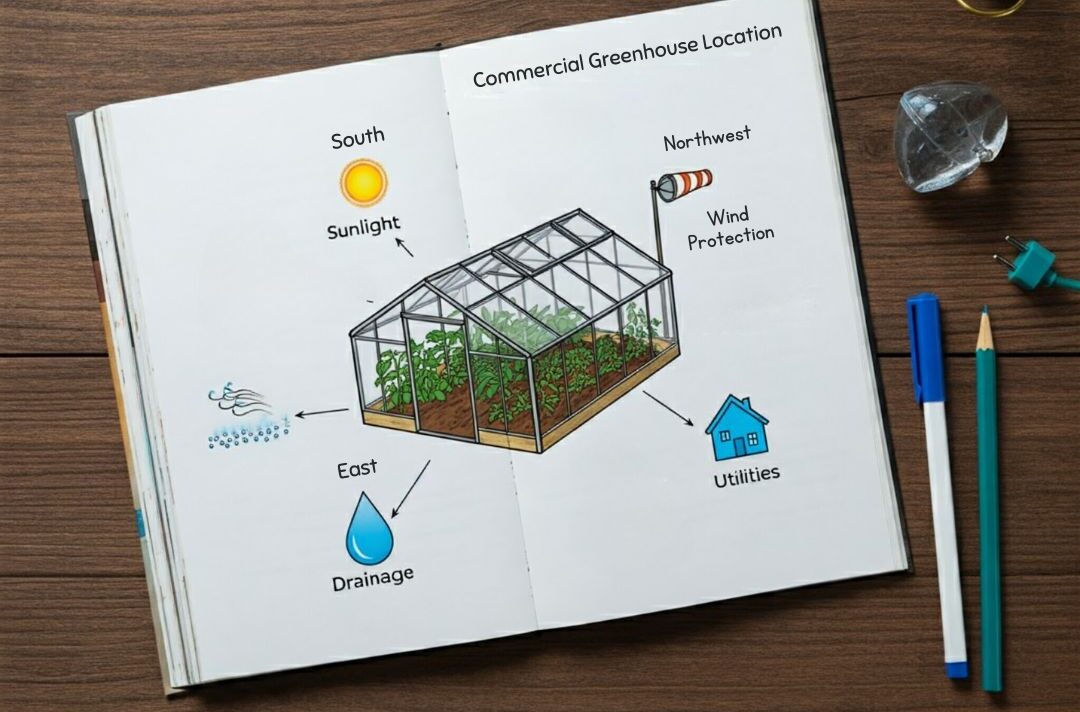

We also talked about the importance of choosing the right location. “Sunlight, drainage, access to utilities – these are all critical factors,” Patrick reminded me. “And don’t forget about zoning and permits! It’s always best to check with your local authorities early on.”

Location, Location, Location: Finding the Perfect Spot for Your Commercial Greenhouse

As Patrick wisely pointed out, “Location is key.” Choosing the right site for your commercial greenhouse can significantly impact its success and profitability. So, let’s answer the question: “How to decide where to put a greenhouse?”, drawing insights from agronomist forums and trusted blogs from 2020 to 2024.

What is the best orientation for commercial greenhouses?

- Maximize Southern Exposure: In the Northern Hemisphere, orient your greenhouse to face south to capture the most sunlight throughout the year. This is especially important during winter months when daylight hours are shorter.

- Minimize Shading: Avoid areas with tall buildings, trees, or other obstructions that cast shadows on your greenhouse. Even partial shading can significantly reduce light levels and impact plant growth.

- Consider Topography: If your site has slopes, choose a south-facing slope for optimal sun exposure. Avoid valleys or low-lying areas where cold air can settle, potentially damaging your crops.

Drainage: Essential for Healthy Roots

Drainage is absolutely critical for healthy plant growth in your commercial greenhouse. Whether you’re using traditional soil or soilless systems, ensuring proper drainage is non-negotiable. For soil-based greenhouses, start by assessing the soil’s drainage capacity. Waterlogged soil can suffocate roots and lead to root rot, spelling disaster for your crops. Conduct a simple soil test to determine its drainage capabilities and amend the soil if necessary to improve its structure and drainage.

If you’re opting for soilless systems like hydroponics or growing bags, remember that proper drainage for excess water and nutrient solution is still vital. Elevated beds or tables are excellent choices, as they facilitate drainage and promote healthy airflow around the root zone. No matter your chosen growing method, avoid locating your greenhouse in flood-prone areas or areas with high water tables. Flooding can wreak havoc, damaging your greenhouse structure and decimating your valuable crops.

Access to Utilities: Power & Water

Having reliable access to power and water is essential for any commercial greenhouse operation. Your greenhouse kit relies on electricity to power everything from lighting and climate control systems to irrigation pumps and automated systems. Choose a location with a dependable power supply and consider investing in backup power options, such as a generator, to safeguard your operation against potential outages. Water is equally crucial for irrigation and other essential greenhouse processes. Ensure your chosen site has access to a clean and abundant water source, whether it’s a municipal water supply, a well, or a rainwater collection system.

Zoning & Permits: Navigating Regulations

Before you break ground on your greenhouse project, it’s crucial to navigate the regulatory landscape. Consult with your local authorities to ensure your plans comply with zoning regulations, which can vary significantly from one area to another. Some areas may have restrictions on greenhouse size, placement, or even the types of crops you can grow. Depending on the scale of your operation, you’ll likely need to obtain building permits and other regulatory approvals. Factor in the time and costs associated with this process to avoid any surprises down the line.

Additional Considerations:

- Accessibility: Ensure easy access for deliveries, equipment maintenance, and harvesting.

- Security: Consider security measures to protect your valuable crops and equipment.

- Proximity to Markets: If possible, locate your greenhouse near your target market to reduce transportation costs and ensure fresh produce reaches consumers quickly.

Making Smart Choices

“Alright, Patrick,” I said, leaning forward, “we’ve covered a ton, but let’s talk about the grower’s perspective. How do they make sure they’re making the right choices for their operation? Where to buy best greenhouse?”

Patrick smiled, “It’s all about doing your homework. Don’t rush into anything. Take your time, explore different options, and talk to other growers. See what’s working for them, what challenges they’ve faced.”

He paused, then continued, “Get multiple quotes, too. Don’t just go with the first price you see. And if you’re feeling overwhelmed, don’t be afraid to reach out to experts – consultants, engineers, folks who’ve been in the game a while.They can be a lifesaver.”

“And think long-term,” Patrick added, tapping his finger on the table for emphasis. “It’s easy to get caught up in the initial price tag, but a well-built greenhouse is an investment. It should last you decades and pay for itself many times over. Look into financing options if you need to; there’s help out there.”

His words resonated with me. Investing in commercial greenhouses is a big step, but with the right planning and support, it can be a game-changer for growers.

Does a commercial greenhouse construction need a foundation?

Okay, Patrick, let’s talk foundations. Does a greenhouse really need one?”

Patrick nodded, “It’s a crucial question, Noam. For hobby greenhouses, a simple base might do. But for commercial greenhouses, a proper foundation is essential. It provides stability against the elements, helps with drainage, and supports heavy equipment.”

He added, “At DeCloet, we work with various foundation options to suit different needs. We can help you find the right solution for your specific site and greenhouse.”

I understood. Foundations were clearly more than just a construction detail; they’re vital for a commercial greenhouse’s long-term success.

Planning for Growth

“One more thing, Patrick,” I said, “scalability. A lot of growers start small but dream big. What advice do you have for them?”

“That’s a great point, Noam. You don’t want to paint yourself into a corner. Look for a greenhouse system that can grow with you. Modular designs are great for that – you can add on as your business expands.”

He leaned back in his chair, thoughtful for a moment. “And don’t forget about the bigger picture. Do you have enough land for future expansion? Can your water and power supply handle increased production? These are all things to consider upfront.”

Patrick’s advice was practical and insightful. Planning for the future is crucial in the ever-evolving world of commercial agriculture.

Me: “Okay, Patrick, let’s say a grower is ready to take the plunge. What’s a good size for a commercial greenhouse?”

Patrick: “That’s a bit like asking how long a piece of string is, Noam. It really depends on the grower’s goals and available space.”

He continued, “But I can give you some general guidelines. For smaller operations or those just starting out, freestanding commercial greenhouses around 24′ x 48′ can be a good starting point. It offers enough space to get your feet wet without overwhelming you.”

“For large scale commercial growers,” Patrick said, “our GrowMax series comes in widths of 30 feet and 40 feet, while our Grower’s Choice gives you a 30’ and a 35’ option. You can connect several bays to make a large growing area. We’ve seen growers successfully operate with structures spanning several acres! Our Gutter Connect Structures range from 21’ to 48’ wide, with the maximum ventilation solution always in the forefront of our design.”

What is the height of commercial greenhouses?

He paused, then added, “Remember, it’s not just about the square footage. You also need to consider the height of your commercial greenhouse. Taller structures are ideal for crops that vine or require trellising, like tomatoes or cucumbers. Plus, they offer better air circulation and temperature control.”

I nodded in agreement. Commercial Greenhouses size is a balancing act between production goals, available space, and budget constraints. It’s crucial to plan carefully and consider future expansion possibilities.

Patrick’s final words on the matter were simple but impactful: “Don’t be afraid to start small and scale up as your business grows. The beauty of modular designs like our Gutter Connect system is that you can easily add on as needed. It’s all about finding the right balance for your unique operation.”

In Summary

As our conversation drew to a close, I couldn’t help but feel a sense of optimism. The challenges of building and running a greenhouse are real, but with careful planning, expert guidance, and a focus on long-term goals, growers can set themselves up for success. Remember, it’s an investment in your future, and the rewards can be bountiful.

For more information we are recommend to Visit Official DeCloet Greenhouses Website – https://www.decloetgreenhouse.com/gutter-connect

Environment systems for your greenhouse with integrated AI – https://growdirector.com/