PAR Sensor vs. Lux Sensor: The Professional Grower’s Guide to Measuring Light for Profit

In commercial farming, every input is a cost that must be managed to ensure profitability. While water, nutrients, and CO2 are meticulously controlled, the single most important driver of growthlightis often misunderstood or measured with the wrong tools. The choice between a PAR sensor and a light Lux sensor isn’t a minor technical detail; it’s a fundamental business decision that directly impacts your energy costs, crop consistency, and bottom line.

This guide will break down the critical differences between these two technologies, explain why professional growers rely on PAR-based measurements, and show you how the right photosynthetically active radiation sensor transforms light from an unpredictable variable into a controllable, profitable asset.

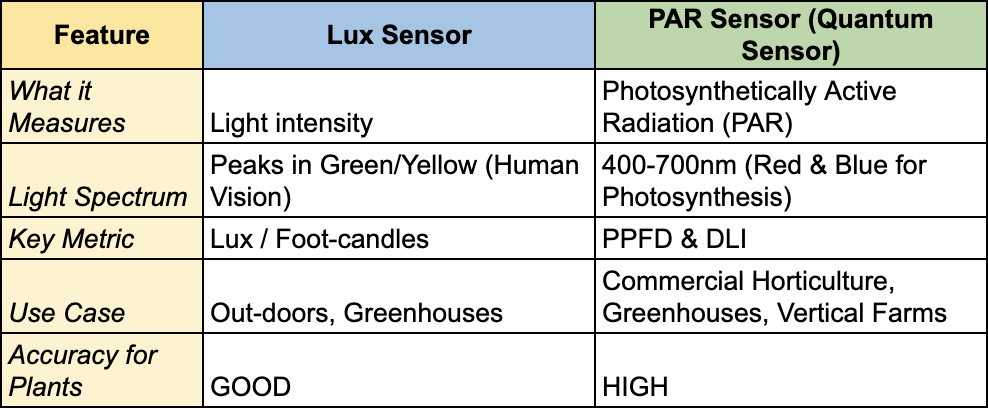

What’s the Difference Between a PAR Sensor and a Lux Sensor?

A common point of confusion is the idea that one sensor is simply better than the other. In reality, a lux sensor and a PAR sensor are different tools designed to measure different things. They effectively speak two different languages of light.

The Lux-meter: Measuring the Intensity of Full-Spectrum Light

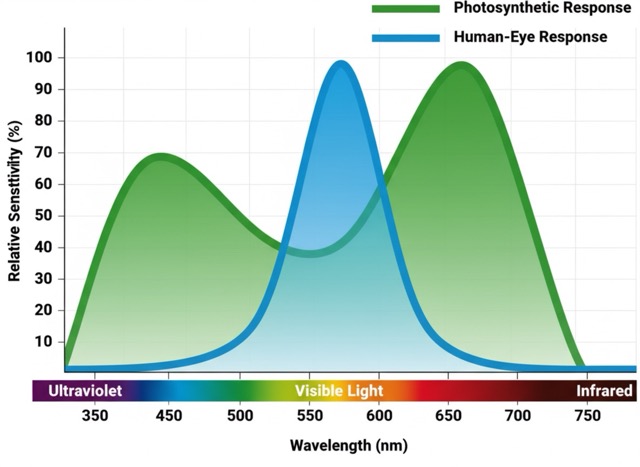

A lux sensor measures illuminance – the intensity of light as perceived by the human eye, in units of lux or foot-candles. Our eyes are most sensitive to the green and yellow part of the spectrum, so a lux sensor gives higher readings for light rich in these wavelengths.

This is a perfectly valid and useful measurement when your primary light source is the full-spectrum sun. Natural sunlight contains all the wavelengths plants need for healthy growth. In a sun-drenched greenhouse, a lux sensor provides an excellent measure of the overall brightness and intensity of that natural light. It’s a practical tool for making broad decisions, like when to deploy shade cloths to prevent overheating

The PAR Sensor: Measuring What Truly Matters to Plants

A PAR sensor, professionally known as a quantum sensor, is the correct tool for horticultural applications. It is specifically designed to measure

Photosynthetically Active Radiation (PAR) – the precise range of light (400 to 700 nm) that plants use for photosynthesis.

Instead of measuring brightness as humans see it, a PAR sensor counts the actual number of photons in the most crucial red and blue spectrums that drive plant growth . This measurement becomes absolutely essential when you are managing artificial or supplemental lighting, where the quality and spectrum of light are just as important as the intensity.

The Language of Profitable Growth: Understanding PPFD and DLI

A PAR sensor provides the raw data needed to manage light effectively, but to use that data, growers rely on two key metrics: PPFD and DLI.

- PPFD (Photosynthetic Photon Flux Density): This is the measure of light intensity. It tells you how many photons of PAR light are landing on a square meter of your crop canopy each second. The unit is micromoles per square meter per second. Think of PPFD as the speed at which water is filling a bucket. A higher PPFD means the “water” (light) is flowing faster. A PPFD sensor is simply another name for a PAR or quantum sensor.

- DLI (Daily Light Integral): This is the measure of the total amount of PAR light your crop receives over a 24-hour period. It is the cumulative dose of light available for photosynthesis, expressed in moles per square meter per day. To continue the analogy, DLI is the total amount of water collected in the bucket at the end of the day.

For commercial growers, DLI is the single most important metric for light management. Decades of research have established precise target DLI ranges for virtually every commercial crop, and there is a direct correlation between achieving the correct DLI and maximizing yield.2 As a rule of thumb, a 1% increase in DLI often correlates to a 1% increase in yield.

The Right Tool for the Right Job: Matching the Sensor to Your Environment

The decision to use a lux or PAR sensor depends entirely on your growing environment and your specific operational goals.

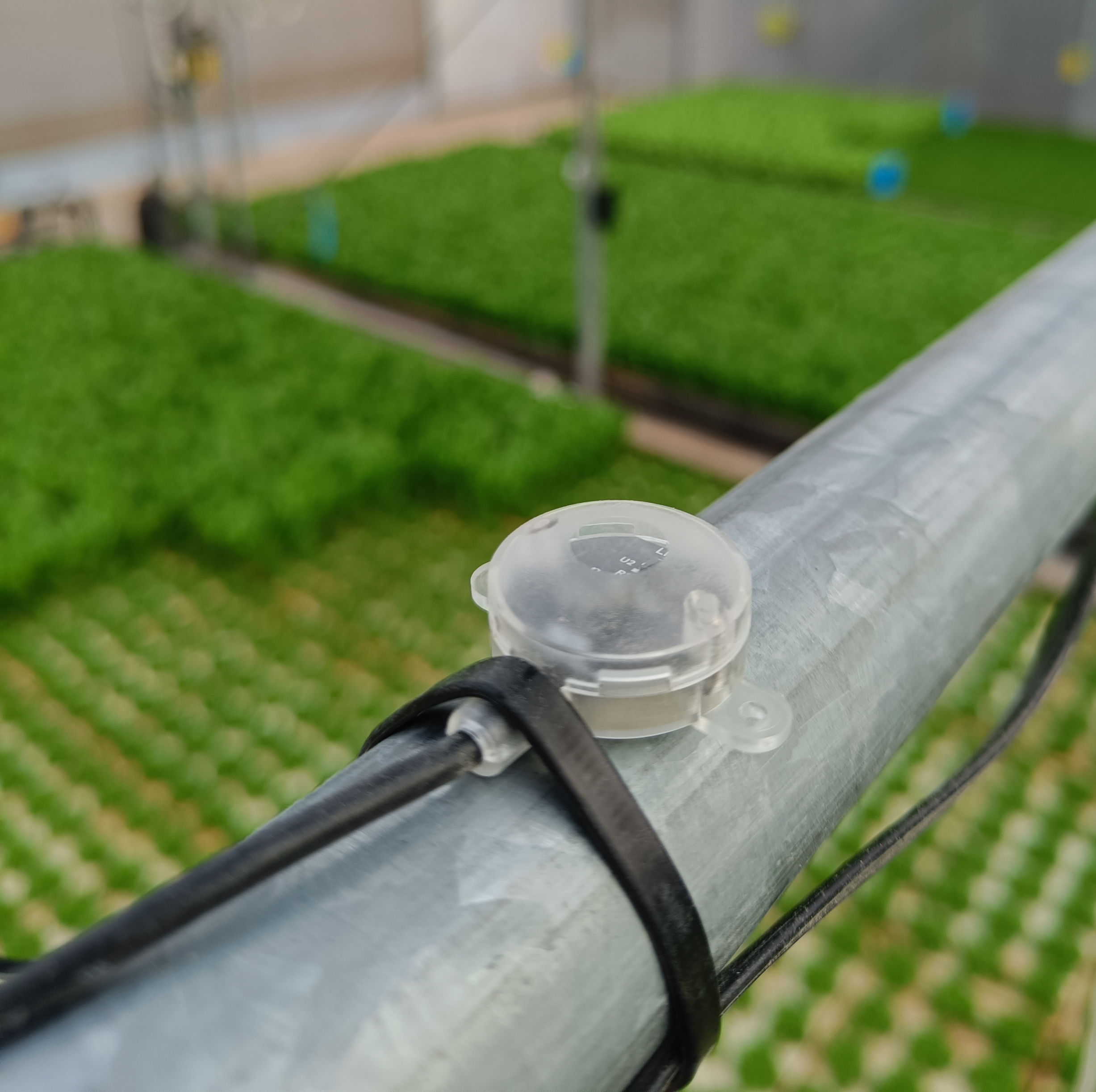

- For Greenhouses Managing Natural Light: In a setting like the large greenhouse pictured, where the sun is the primary light source, a lux sensor is a practical tool for managing overall light intensity. It can effectively trigger systems like automated shade curtains when the sun’s brightness reaches a certain threshold, protecting crops from damage .

- For Indoor & Vertical Farming: In a closed environment like the vertical farm shown, where there is no sunlight and the only light source is specialized LEDs, a PAR sensor is non-negotiable. The pink light from these LEDs is rich in red and blue wavelengths (high PAR) but would register as dim and inaccurate on a lux sensor . Only a PAR sensor can correctly measure the photosynthetic light driving growth in this setting.

- For Professional Supplemental Lighting: For any commercial operation using supplemental lights (like the HPS lamps in the greenhouse image or modern LEDs) to augment the sun, a PAR sensor is the required tool for precision and profitability. Its job is to measure exactly how much photosynthetic light the supplemental fixtures are adding, allowing the control system to calculate the total DLI and run the expensive lights only when necessary to hit the daily target. This is the key to managing energy costs and guaranteeing consistent yields

Why a PAR Sensor is a Critical Investment for Commercial Growers

Understanding the science is important, but the real reason growers invest in quantum sensors (often called PAR light sensors) is purely economic. It is a tool for risk management that provides a clear and rapid return on investment (ROI).

Slash Energy Costs with Data-Driven Automation

Supplemental lighting is one of the largest operating expenses for a greenhouse, accounting for up to 30% of total costs. Without precise measurement, growers are forced to run lights on a fixed timer, wasting thousands of dollars on electricity during sunny periods when free, natural light is abundant.

PAR or Quantum sensors integrated with an environmental control system like GrowDirector eliminate this waste.

- The grower inputs the target DLI for the crop.

- The quantum (ePAR) sensor is placed above the shade system, continuously measuring the natural sunlight.

- The control system calculates the difference between the accumulated sunlight and the daily target. It then automatically turns on, turns off, or dims the supplemental lights to provide only the exact amount of light needed to hit the DLI target by the end of the day.

This dynamic, real-time control is proven to be highly effective. Case studies show that implementing sensor-based dimming and automation can reduce annual electricity bills by 25% to 30% without any loss in yield.

Guarantee Consistent Yields and Quality

Inconsistent light levels lead to non-uniform crops, delayed harvests, and a lower percentage of premium-grade product.3 By using quantum sensors to ensure every plant receives its optimal DLI every single day, regardless of weather, you remove the primary source of growth variability.

This consistency generates financial returns by:

- Improving Uniformity: Plants grow at the same rate, leading to a uniform harvest that meets the strict specifications of commercial buyers.

- Predictable Scheduling: Harvest dates become reliable, allowing you to confidently commit to delivery schedules and manage labor more efficiently.

- Maximizing Yield: By consistently hitting the scientifically proven DLI target for your crop, you are ensuring the maximum possible rate of photosynthesis and, therefore, the highest potential yield.

Frequently Asked Questions About PAR Sensors

Q: Can I just use a cheap lux meter and convert the reading to PAR?

While online calculators exist to convert lux to PPFD, this method is highly inaccurate for a professional setting. The conversion factor changes dramatically depending on the light source (e.g., the sun, an HPS lamp, or different types of LEDs). Using a converted lux reading to control your lighting system can lead to providing too little of the right kind of light or wasting energy on the wrong kind, defeating the purpose of measurement.

Q: What are quantum sensors? Is it different from a PAR sensor?

The terms are often used interchangeably. Quantum sensors is the scientific term for these devices because they measure the quantity of light photons, due to the quantized nature of radiation. In the horticulture industry, they are commonly called PAR sensors because they are designed to measure light specifically within the Photosynthetically Active Radiation (PAR) spectrum.

Q: How many Quantum Sensors do I need for my greenhouse?

For optimal accuracy, it is recommended to use more than one sensor per lighting zone. This allows the control system to take an average reading, which prevents the entire zone’s lighting from turning on or off if a single sensor is temporarily shaded.

Q: What should I look for when buying a PAR light sensor?

For commercial use, look for a sensor with a rugged, self-cleaning housing (often anodized aluminum with an acrylic diffuser) to withstand the greenhouse environment. Ensure it is designed for easy connection to data loggers and controllers. Most importantly, choose a sensor that integrates seamlessly with your environmental control system to enable true, data-driven automation.

The Clear Choice for Profitability

For the hobbyist, a LUX sensor light meter might be a starting point. But for a commercial professional, where energy costs are a major liability and crop consistency is paramount, the choice is clear. A PAR sensor (also known as a quantum sensor) is not a luxury; it is a fundamental tool for profitable farming. It allows you to speak the same language as your plants, providing the precise energy they need while protecting your bottom line.