8 Steps to Choose the Perfect Greenhouse Automation for Professional Growers in 2025

Greenhouse automation is the use of technology to control the environment in a greenhouse. This can include things like controlling the temperature, humidity, light levels, and irrigation. New technologies can help growers to increase yields, improve quality, and reduce labor costs.

What are the benefits of greenhouse automation?

Before diving into how to choose the right greenhouse automation system, it’s crucial to understand the significant benefits of greenhouse automation. These advantages are what drive the return on investment and transform a growing operation, turning potential into profit.

-

- Maximized Yields: Precise environmental control leads to optimal plant growth and increased yields, translating to higher profits.

- Enhanced Crop Quality: Consistent and controlled conditions result in superior crop quality, attracting premium prices in the market.

- Reduced Labor Costs: Automation reduces the need for manual intervention, freeing up labor for more strategic tasks.

- Resource Efficiency: Smart automation minimizes water and energy usage, contributing to sustainable and eco-friendly practices.

- Real-Time Monitoring: Stay connected to your growing facility from anywhere, receiving instant alerts for timely responses to deviations.

- Pest and Disease Management: Early detection of pests and diseases allows for proactive measures, preventing crop damage and loss.

- Customization and Scalability: Tailor the system to fit your specific requirements and expand it as your business grows.

- Improved Decision-Making: Access to comprehensive data and analytics empowers growers to make informed and data-driven decisions.

What to Expect from a Newest Greenhouse Automation Platform?

The concept of greenhouse automation has evolved significantly. Early systems were simple, staged controllers for basic climate management. Today, leading platforms are fully integrated, intelligent systems that act as the central nervous system for a growing operation. When evaluating modern solutions, professional growers should look for four key attributes that define a next-generation system: modularity, AI integration, robust hardware, and a hybrid control architecture.

- Limitless Modularity: A state-of-the-art system is built on a wireless, modular architecture that allows it to scale with your success. Rather than a single, monolithic controller, these platforms consist of specialized modules for different functions. “Built-to-scale” approach allows growers to start with what they need and expand effortlessly as their operation grows, ensuring the technology adapts to the business, not the other way around.

- AI-Driven Intelligence: The most advanced platforms now integrate enhanced AI functionality to move from reactive control to proactive management. This includes AI-driven predictive crop disease diagnosis, agronomic recommendations based on real-time data, and smart data summaries that provide actionable insights.

By leveraging machine learning and intelligent algorithms, these systems can make predictive adjustments, coordinate equipment seamlessly, and help growers mitigate risks before they impact yield.

- Industrial-Grade Hardware: A greenhouse is a demanding environment with extreme conditions. A modern automation platform must be built to last. Look for systems housed in durable, watertight, industrial-grade enclosures engineered to withstand humidity, temperature swings, and other environmental challenges.

This ensures high-performance, reliable operation and protects your investment from the harsh realities of a grow facility.

- Hybrid Control Architecture: While cloud connectivity is essential for remote access, relying on it completely can be a point of failure. The most resilient systems employ a “Local First, Cloud Enhanced” architecture.

This model combines powerful local-first control, ensuring that all critical operations continue to run reliably on-site without an internet connection, with cloud-enhanced intelligence for data backup, AI insights, and remote management from any device.

This hybrid approach guarantees uninterrupted performance, zero system downtime, and automatic self-recovery.

How Automation of Greenhouse is Solving Horticultural Challenges in Different Countries

Automated plant cultivation is being used in different countries to solve horticultural challenges.

For example, in the Netherlands, smart controllers are being used to increase yields and improve quality. The Dutch company Priva has developed a horticulture automation system that uses sensors to monitor the environment and adjust the climate accordingly. This system has helped Dutch growers to increase their yields by up to 20%.In Israel, new technology is being used to grow crops in a desert climate. The GrowDirector has developed an intelligent climate control system for indoor and greenhouse horticulture. This system has helped commercial growers all over the world to save water and increase their yields

In Middle East, new technology is being used to grow crops in a desert climate. The company GrowDirector has developed an intelligent climate control system for commercial greenhouse horticulture.

GrowDirector 4 PRO – greenhouse automation that can help you improve your yields, quality, and profitability.

In North America, automation is proving vital for large-scale producers. In Canada, Great Lakes Greenhouses in Ontario, a leading cucumber grower, implemented Koidra’s AI technology and achieved a 19.6% increase in cucumber yield while improving energy efficiency by 17%. In the United States, multi-national supplier Costa Farms uses automation modules to monitor external weather and automatically adjust the greenhouse environment, closing vents during high winds and activating shade systems in response to intense sunlight.

How to Choose the Right Greenhouse Automation System for Professional Growers

High-tech horticulture is a powerful tool that can help professional growers to improve their yields, quality, and profitability. However, with so many different systems on the market, it can be difficult to know which one is right for you.

Key Factors for Choosing Greenhouse Automation Equipment:

-

- Specific Goals: Define your objectives clearly. Determine whether you aim to increase yields, improve crop quality, reduce labor costs, enhance resource efficiency, or achieve other specific goals.

- Greenhouse Size: Consider the size of your growing facility. Smaller greenhouses may not require complex systems, while larger ones may benefit from more sophisticated solutions.

- Crop Type: Different crops have unique environmental requirements. Ensure the automation system aligns with the specific needs of the crops you grow, such as temperature control or specialized irrigation.

- Budget: Set a budget for the automation system. Balance your desired features and capabilities with the financial resources available.

- System Features: Evaluate the features of the automation system. Look for capabilities like real-time monitoring, pest and disease detection, remote accessibility, and scalability.

- Ease of Use: Opt for an intuitive and user-friendly system, especially if you have a small team or limited technical expertise.

- Reliability: Choose a system with a proven track record of reliability and minimal maintenance requirements.

- Customer Support: Select a provider that offers excellent customer support, ensuring assistance when needed.

Smart Systems Available on the Market:

GrowDirector 4 PRO: This system is designed for professional growers and is built on a wireless, modular architecture that allows for limitless scalability. It features specialized modules for lighting, fertigation, and equipment control, all housed in industrial-grade, watertight enclosures. The platform integrates advanced AI for predictive disease diagnosis and agronomic recommendations and uses a “local first, cloud enhanced” architecture to ensure uninterrupted performance.

Argus Control System: Also designed for professional growers, the Argus TITAN system is a powerful, integrated solution for managing an entire horticultural facility, from climate and lighting to advanced irrigation and fertigation. It offers extensive data logging and can be accessed remotely via the cloud-based TITAN Envoy interface on desktop or mobile devices.

GrowLink system: This one is for smaller growers and can monitor plants for pests and diseases, control the temperature and humidity, and automatically water plants.

Priva: A leading Dutch company, Priva offers the Connext process computer to connect and manage all greenhouse processes in one integrated system. It focuses on efficiently managing climate, water, and energy, with remote operation and monitoring available through the cloud-based Priva Connected service package.

Wadsworth Controls: A US-based company known for its durable and reliable systems, Wadsworth offers the user-friendly Juniper controller for managing heating, cooling, vents, and curtains. For more complex operations, their Seed control system provides advanced integrations. Both can be accessed remotely via the Wadsworth.Cloud platform.

Spagnol: This Italian company provides a range of configurable and expandable controllers like the C-Fenix and F-Fenix. They are designed for precise control over climate and fertigation strategies, allowing growers to set precise treatments to optimize microclimatic conditions. The entire system can be supervised remotely via their Vision software.

Autogrow: Autogrow’s modular MultiGrow system can manage the climate and dosing for up to eight different growing zones from a single controller. It provides secure remote access via a web browser and performs daily data backups to ensure settings and historical data are preserved.

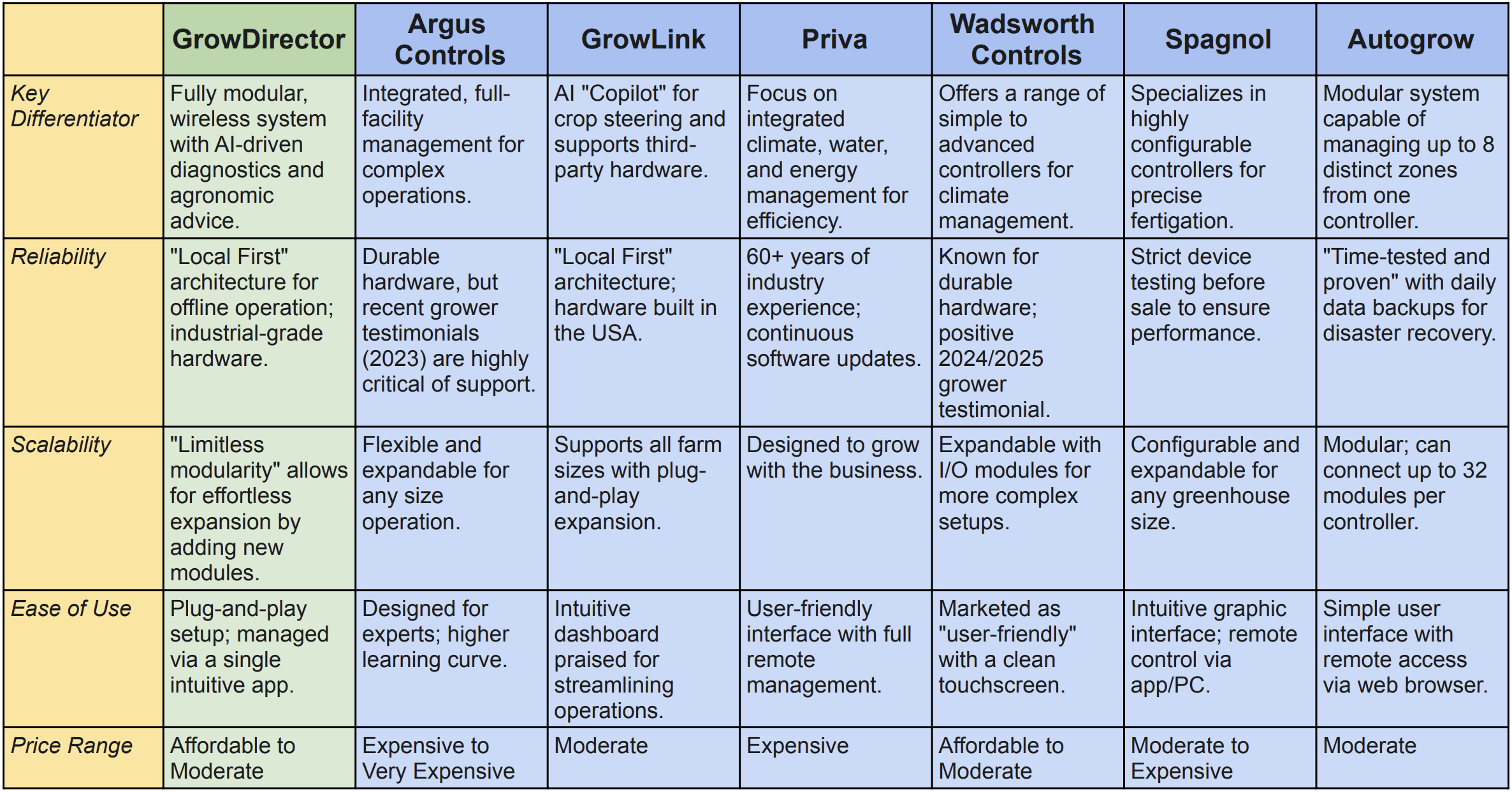

Lets compare greenhouse automation:

Tips for professional growers to choose the right greenhouse automation system:

- Start small: If you’re new to automated horticulture, it’s a good idea to start small. You can always add more features or modules to your system later on.

- Get professional advice: If you’re not sure what type of system is right for you, it’s a good idea to get professional advice. A professional agronomist can help you assess your needs and recommend a system that’s right for you.

- Be prepared to invest: Controllers can be a significant investment, but it’s important to remember that it can save you money in the long run. By automating tasks such as watering and harvesting, you can free up your time to focus on other things, such as marketing and sales.

With careful planning and execution, smart controllers can be a valuable tool for professional growers who want to improve their yields, quality, and profitability.

The Future

The future of precision greenhouse management is bright. As technology continues to advance, greenhouse automation will become more sophisticated and affordable. This will make it possible for even small-scale growers to benefit from the advantages of smart equipment.

Greenhouse automation is a valuable tool for growers who want to increase yields, improve quality, and reduce labor costs. By choosing the right system and using it effectively, growers can improve their bottom line and achieve their production goals.