The Best Automated Hydroponic System: A Definitive Guide for Commercial Growers

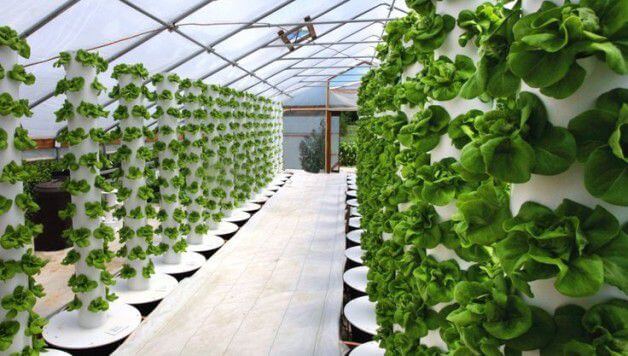

In the world of commercial agriculture, precision is profit. For large-scale greenhouse operators, the conversation has shifted from if hydroponics is viable to how to optimize it for maximum return on investment. The answer, increasingly, lies in technology. This guide is designed to be the ultimate resource for commercial growers, greenhouse builders, and agricultural investors exploring the best automated hydroponic system for their operations in 2025. We will move beyond the theoretical and dive into the practical, data-driven realities of automated hydroponic systems, focusing on what truly matters: reliability, scalability, and the direct impact on your bottom line. Our goal is to cut through the noise and provide a clear, professional roadmap to selecting and implementing the technology that will define the next generation of profitable farming.

Foundational Question: Can Hydroponics Be Automated?

The short answer is yes. The more critical business question is, can you afford not to automate? As we look at the operational data from leading commercial growers in 2024 and 2025, a clear trend emerges: hydroponics automation is no longer a luxury, but a competitive necessity.

The primary driver is the reduction of operational costs, specifically labor. Manual monitoring, nutrient dosing, and pH balancing for a facility spanning thousands of square feet is not just labor-intensive; it’s prone to human error. An inconsistent nutrient mix or a pH drift over a weekend can lead to nutrient lockout, stressed plants, and a measurable dip in yield quality and quantity.

Automated hydroponic systems replace this inconsistency with machine-level precision. Sensors continuously monitor key metrics like pH, electrical conductivity (EC), water temperature, and dissolved oxygen. Actuators, controlled by a central system, automatically dose nutrients and pH adjusters with precision down to the milliliter. This creates an optimal and incredibly stable root-zone environment, 24/7. The business case is compelling:

- Reduced Labor Costs: Data from commercial operations indicates a potential reduction in labor dedicated to nutrient and irrigation management by as much as 70-80% after implementing a robust automation platform.

- Increased Consistency and Yield: By eliminating the peaks and valleys of manual management, automation ensures crops are never without the exact resources they need. This consistency directly translates to faster growth cycles and higher, more predictable yields.

- Data-Driven Decisions: True automation provides a constant stream of data, allowing growers to move from reactive problem-solving to proactive optimization.

Defining the Best Automated Hydroponic System: What to Look For

Choosing the best automated hydroponic system for a commercial operation isn’t about finding a single “best” product, but about identifying the best-fit platform for your specific crops, scale, and business goals. However, there are non-negotiable features that separate professional-grade systems from glorified hobbyist timers.

- Centralized Control and Remote Access: Your entire operation—from nutrient dosing to irrigation schedules across multiple zones—should be controllable from a single, intuitive dashboard. Cloud-based access is now standard, allowing you and your head grower to monitor and adjust parameters from any device, anywhere in the world.

- Sensor Integration and Reliability: The system must support a suite of industrial-grade sensors (pH, EC, temperature, dissolved oxygen, etc.). Durability and accuracy are paramount; faulty sensor readings can be more damaging than no readings at all.

- Scalability and Modularity: The system you invest in today must be able to grow with your business. Look for a modular design that allows you to add new zones, sensors, and control features without needing to replace the entire platform.

- Advanced Dosing Capabilities: Professional systems offer multi-part nutrient dosing (e.g., A/B/C formulas plus additives) with precise calibration. This allows for crop-specific feeding regimens that can be adjusted based on the growth stage.

- Data Logging and Analytics: The system should not just act but also record. Comprehensive data logging is the foundation for optimization. The best automated hydroponic system will offer clear visualizations and reports, turning raw data into actionable business intelligence.

System Types and Reliability: What is the Most Reliable Hydroponic System?

Reliability in a commercial context means predictability and durability with minimal downtime. While many hydroponic methods exist, three have risen to the top for large-scale commercial use due to their efficiency and compatibility with automation: Nutrient Film Technique (NFT), Deep Water Culture (DWC), and Drip Irrigation.

Comparing Systems for Commercial Viability

- Nutrient Film Technique (NFT): This is the go-to system for leafy greens, herbs, and other fast-growing, lightweight crops. A thin film of nutrient solution flows continuously over the bare roots of plants in a shallow channel.

- Commercial Reliability: NFT is highly efficient in its use of water and nutrients. Its primary vulnerability is a reliance on the pump; a power outage or pump failure can lead to roots drying out very quickly. Therefore, a robust automation system with alerts and backup power is absolutely critical for a commercial NFT setup. For lettuce production, its efficiency is nearly unmatched.

- Deep Water Culture (DWC): In DWC, plants are suspended in net pots with their roots submerged in a large reservoir of highly-oxygenated nutrient solution.

- Commercial Reliability: DWC is exceptionally reliable and forgiving. The large volume of water acts as a buffer, making the system resilient to short-term power outages or pump failures. It’s also less prone to the clogging issues that can affect other systems. While it’s excellent for leafy greens, commercial-scale DWC for larger plants like tomatoes can be capital-intensive due to the sheer volume of water required.

- Drip Irrigation Systems: This method, often using substrates like coco coir or rockwool, delivers nutrient solution directly to the base of each plant through a network of drip emitters.

- Commercial Reliability: This is arguably the most versatile and widely used system for commercial vining crops like tomatoes, cucumbers, and peppers. It offers precise control over moisture levels in the root zone and is highly scalable. The main reliability concern is clogged emitters, which can starve individual plants. Therefore, high-quality filtration and a control system that can monitor flow rates and pressure are essential components of a reliable automated drip system.

For growers seeking the overall best automated hydroponic system in terms of reliability for diverse crops, a well-engineered drip irrigation system often provides the best balance of control, scalability, and resilience, particularly for heavy-fruiting plants. For specialized leafy green production, NFT remains a top contender, provided it’s paired with fail-safe automation.

The Passive Option: What is the Best Passive Hydroponic System?

While the focus of modern commercial agriculture is on active, controlled systems, it’s worth addressing passive hydroponics. These systems, like the Kratky method or wicking beds, function without pumps or electricity by leveraging capillary action or a non-circulating reservoir.

From a commercial viability standpoint, their application is extremely limited. The lack of active aeration and nutrient circulation makes it difficult to control the root zone environment with the precision needed for uniform, high-yield production at scale. Nutrient stratification and oxygen depletion are significant risks that can lead to inconsistent growth and lower quality.

However, they can have a place in niche commercial applications. For example, a small-scale grower specializing in rare herbs or specific ornamental plants that thrive in less-controlled environments might find a wicking system cost-effective. But for any large-scale operation focused on staple crops and ROI, passive systems lack the control, scalability, and predictability required. The conversation for serious commercial growers inevitably and rightly returns to active, automated hydroponic systems.

The Future of Farming: How to Use AI in Hydroponics

The most significant leap in hydroponics automation in the mid-2020s is the integration of Artificial Intelligence (AI) and Machine Learning (ML). This moves beyond simple “if-then” automation (e.g., “if pH > 6.2, add pH down”) into the realm of predictive and prescriptive control.

AI in hydroponics works by analyzing the vast amounts of data collected by your system’s sensors over time. It correlates environmental data (pH, EC, temperature, humidity, light levels) with operational inputs (nutrient recipes, irrigation schedules) and, most importantly, with yield outcomes.

This data-driven approach allows the system to:

- Predict Outcomes: AI can forecast potential issues like nutrient deficiencies or disease risk based on subtle changes in data patterns, allowing growers to act proactively.

- Optimize Recipes: By analyzing how minor tweaks in the nutrient formula affect growth rates and yield under different conditions, AI can help refine feeding recipes for optimal performance and cost-efficiency.

- Identify Growth Patterns: AI can recognize ideal environmental conditions for specific growth phases (e.g., vegetative vs. flowering) and automatically adjust parameters to create the perfect environment, boosting plant health and accelerating growth cycles.

Leveraging AI-Powered Yield Summaries from GrowDirector for Better Decision-Making

This is where leading platforms like GrowDirector are changing the game. It’s not just about collecting data; it’s about making that data instantly useful. The best automated hydroponic system should provide clear, concise insights that drive business decisions.

GrowDirector’s AI-powered yield summaries are a prime example. The platform synthesizes months of complex sensor and yield data into an easy-to-understand report. A grower can see, at a glance, how a 5% increase in a specific micronutrient during the flowering stage correlated with a 3% increase in total harvest weight across Zone B. This eliminates guesswork and empowers growers to replicate success and systematically improve their entire operation, cycle after cycle. It transforms your greenhouse from a collection of plants into a finely tuned, data-driven production facility.

Conclusion: Your Next Step Towards a More Profitable Future

Choosing the best automated hydroponic system is a pivotal decision for any commercial growing operation. It’s an investment in consistency, efficiency, and long-term profitability. As we’ve explored, the ideal system is scalable, reliable, and built on a foundation of precise sensor technology and centralized control. While NFT, DWC, and Drip systems all have their place, the choice depends heavily on your crop and operational model.

The true competitive edge, however, now lies in the intelligent layer built on top of that automation. By leveraging AI and data analytics, platforms like GrowDirector allow you to not only control your greenhouse but to understand and optimize it on a level that was previously impossible.

If you are ready to reduce labor costs, increase yield consistency, and make data your most valuable asset, the next step is to see how a truly intelligent hydroponics automation system can be tailored to your operation.

Contact GrowDirector today for a personalized consultation and a demo of our AI-powered platform.

contact@growdirector.com

Tel/SMS – 1-516-990-6536