Advanced Greenhouse Management: A Start Up Case Study

Project Information

- Customer: Multi-Crop NFT Grower in Tunnel Greenhouse

- Facility: Tunnel greenhouse, 10,000 sqf

- Method of cultivation: NFT

- Type of crop: multi crops - 75,000 heads / month

Client’s Problem

-

No control over water stability, including fertilizers, pH and dissolved oxygen, no control over the greenhouse inside climate

Grow Director’s Solution & Result

-

The entire greenhouse was automated by connecting all the equipment and sensors under one roof of the GrowDirector 3 PRO system

Manual operations have been reduced by 50%

Equipment used in the case

No data was found

🔧 What was installed?

🔹The HydroPro Kit: HydroDirector, SocketDirector, SensorDirector, DryContactDirector, pH Sensor, EC Sensor, Temperature & Humidity Sensor

🔹 ServerDirector

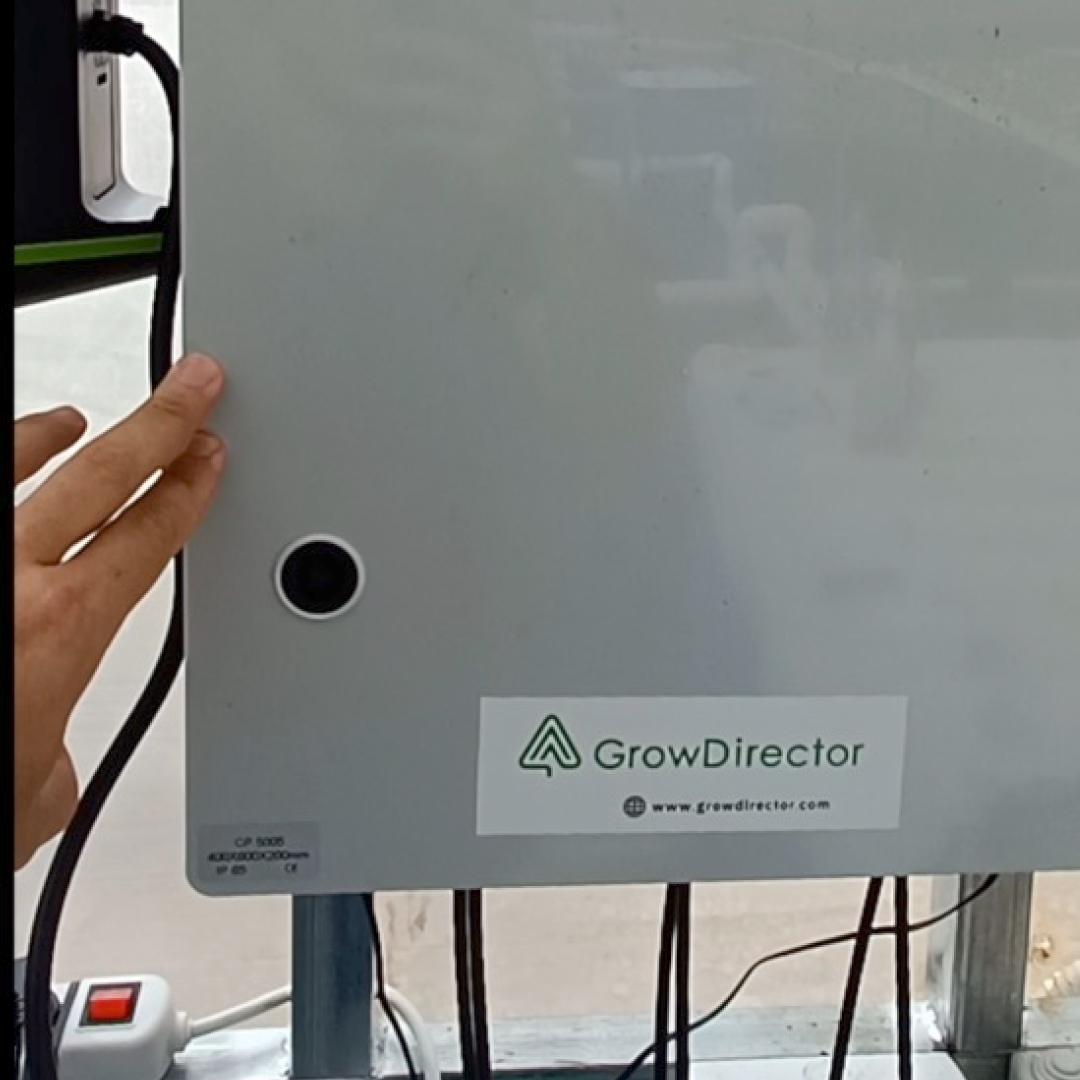

🔹 Protection Against the Elements

This intricate system is the cornerstone of optimization, fostering resource efficiency and superior crop quality.

Our comprehensive kit, thoughtfully integrated into their established infrastructure, unlocked an unprecedented level of control over electric devices and water management.

In parallel, we delivered an ingenious internet solution customized for their remote locale. This bolstered their remote monitoring capabilities, transforming data into actionable insights regardless of geographical boundaries.

To shield their substantial investment from the capricious elements, we fortified their setup with a weather-resistant cabinet.

This proactive measure ensures equipment integrity in the face of unpredictable climatic forces.

For more information on how to supercharge your greenhouse, reach out to us today! 🌱🌦️