Revolutionizing NFT Lettuce Cultivation For The Start Up

Project Information

- Customer: NFT Smart Farming Start Up

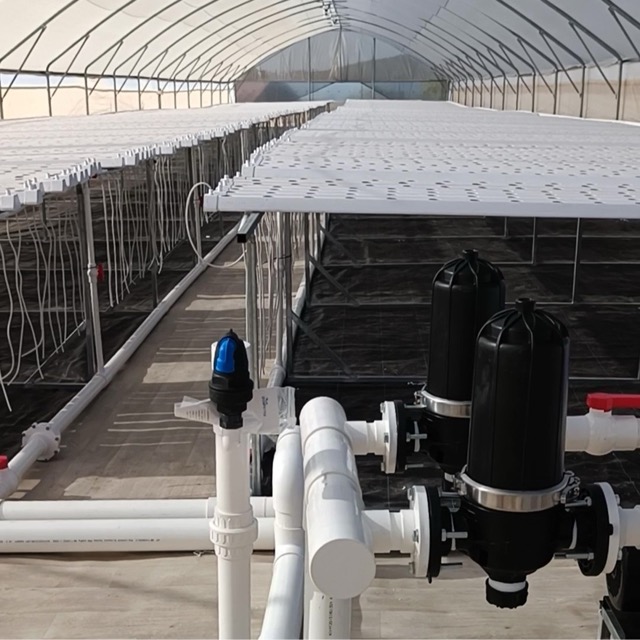

- Facility: net greenhouse, 10,000 sqf

- Method of cultivation: NFT

- Type of crop: 50,000 lettuce heads/month

The Customer's Challenge

-

Fragmented systems causing data blindness

Drifting pH and EC threatening crop safety

High manual overhead draining OpEx

Barriers to performance in climate logic

GrowDirector’s Solution & Result

-

Solution

Centralized control of all capital assets

Precision dosing unit for water stability

Smart relay modules unifying high-voltage pumps

3rd party equipment integration (Design Freedom)

Result

50% reduction in operational expenditure

Secured commercial yield uniformity

Maximized margins via zero-downtime logic

Equipment used in the case

Modernizing Assets Without Pausing Production

Pausing a high-velocity NFT system to install upgrades is a financial risk no commercial grower should accept. We designed our installation process to eliminate the “downtime tax” common with legacy systems. The footage demonstrates how we deploy the automation platform in mere hours, utilizing wireless connectivity to avoid trenching or complex rewiring.

This approach allows the facility to modernize its control logic while key biological processes continue uninterrupted, ensuring the revenue stream remains secure. We deliver the upgrade without ever forcing the operator to stop the pumps.

In commercial NFT projects, even minor fluctuations in water chemistry create a barrier to performance that threatens the entire harvest revenue.

Eliminating the Financial Risk of Climate Conditions Instability