Home

‣

Cases

‣

Fruit and Vegetable Farming

‣

How to Build an Effective High-Tech Greenhouse CapEx Strategy for Scalable Strawberry Production

How to Build an Effective High-Tech Greenhouse CapEx Strategy for Scalable Strawberry Production

Project Information

- Customer: New Commercial Project in Romania

- Facility: 4 Polyhouses

- Method of cultivation: Hydroponics

- Type of crop: Strawberry

Client’s Problem

-

Designing a commercial strawberry farm that balances cost efficiency with industrial-grade reliability.

Piecing together disparate timers and controllers, which would lead to operational chaos and a lack of unified data.

Grow Director’s Solution & Result

-

The Strategy: Deploying a “risk-averse” open architecture and lower greenhouse CapEx using GrowDirector.

The Outcome: A secure, scalable, and capital-efficient operation that sets a new standard for commercial strawberry farm.

Equipment used in the case

The Romanian team chose GrowDirector because of its Local-First Architecture.

Here is their blueprint:

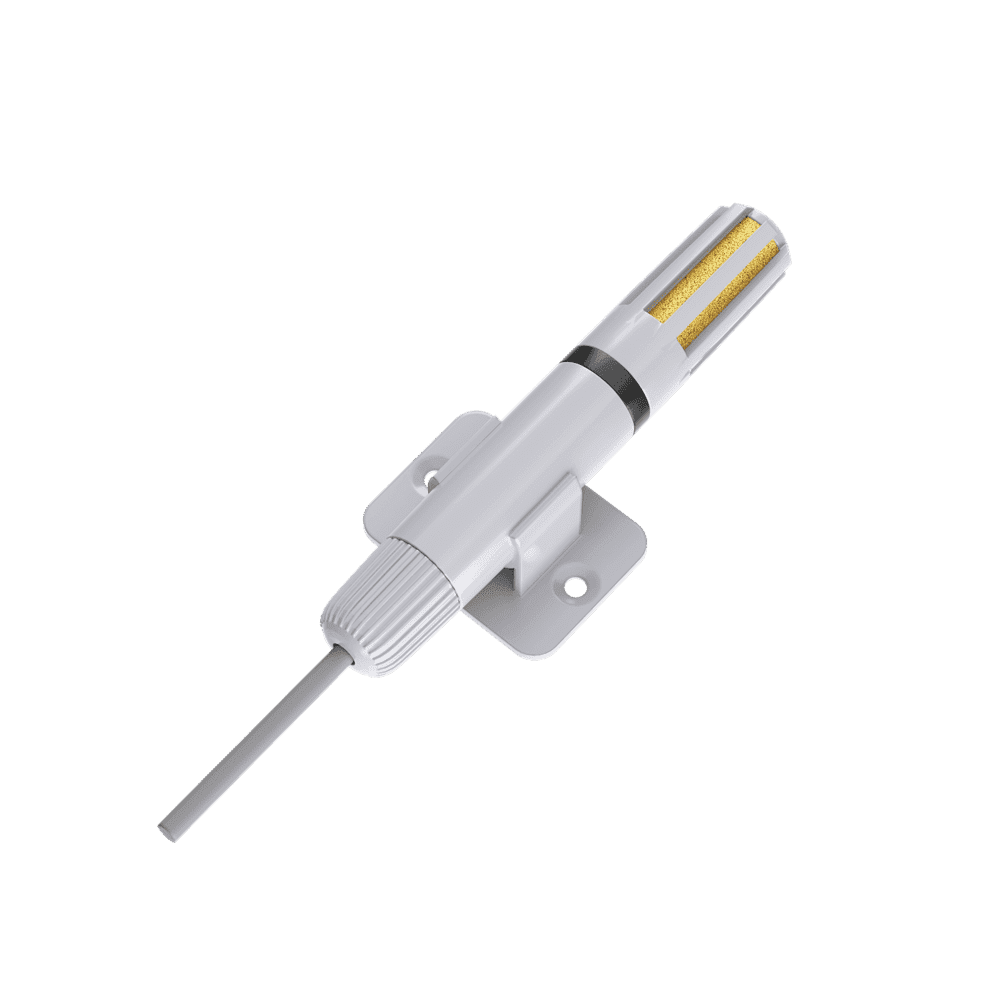

- For Precision Fertigation: The HydroDirector module automates fertigation management with precise pH and EC control using Industrial IoT Sensors.

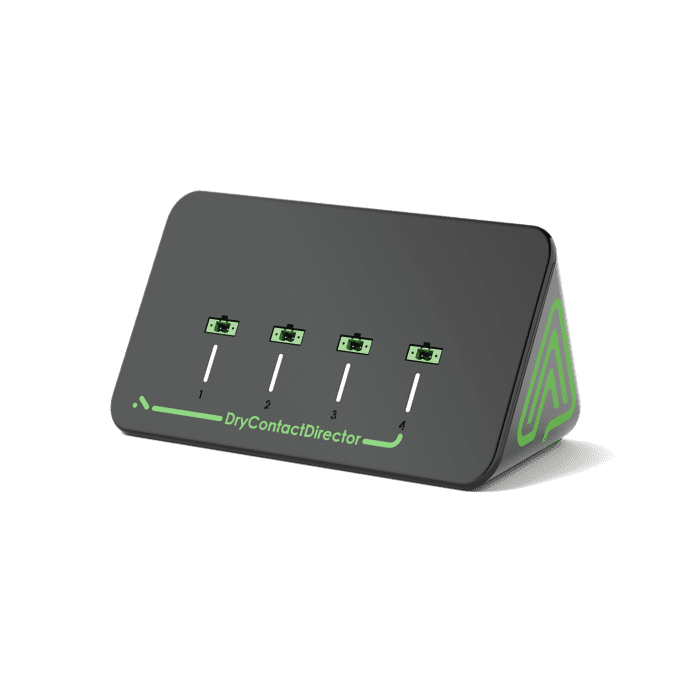

- For HVAC & Equipment Automation: DryContactDirector and SocketDirector modules bring their fans, heaters, chillers, and other electrical equipment under intelligent, centralized control.

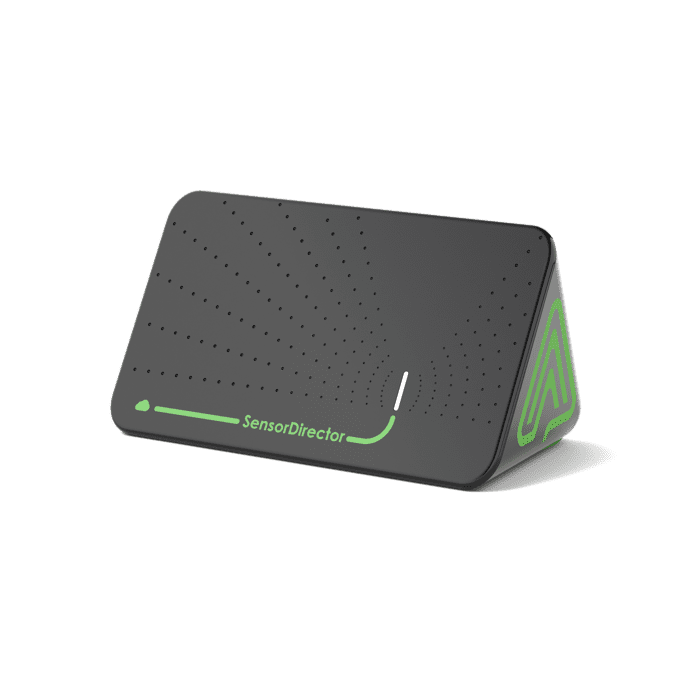

- For Smart Climate Management: The SensorDirector collects and visualizes data from industrial IoT sensors (Temperature, Humidity, and VPD) for smart and precise remote climate control.

Even if the facility loses internet access, the HydroDirector keeps dosing and the DryContactDirector keeps the fans running. This guarantees Operational Continuity.

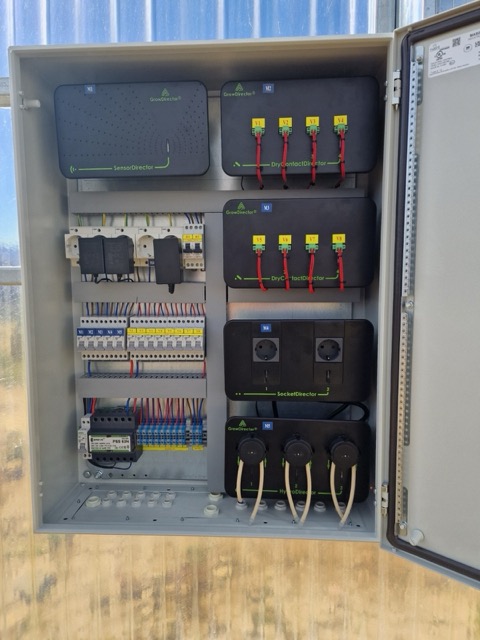

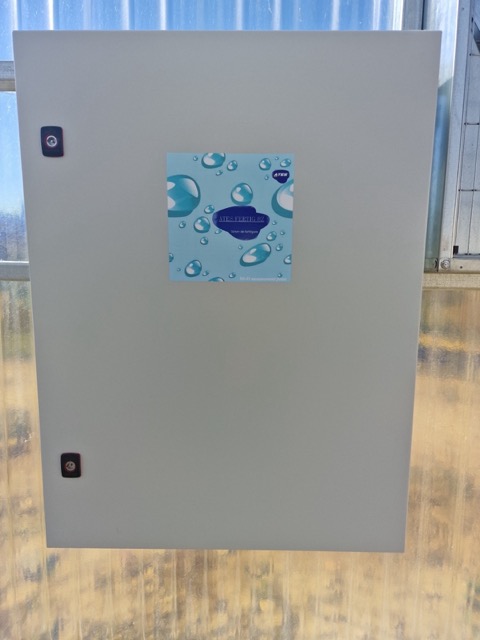

Industrial-Grade Infrastructure

Built for Resilience: The IP65 Protection Standard

A rugged IP65-rated industrial automation enclosure mounted in a Romanian greenhouse, housing the GrowDirector 'local-first' control system to ensure zero-downtime reliability and protection against high humidity and environmental stress.