How to Optimize Your Aeroponic Farm with Precision Greenhouse Control

Project Information

- Customer: A professional grower

- Facility: Modern greenhouse facility

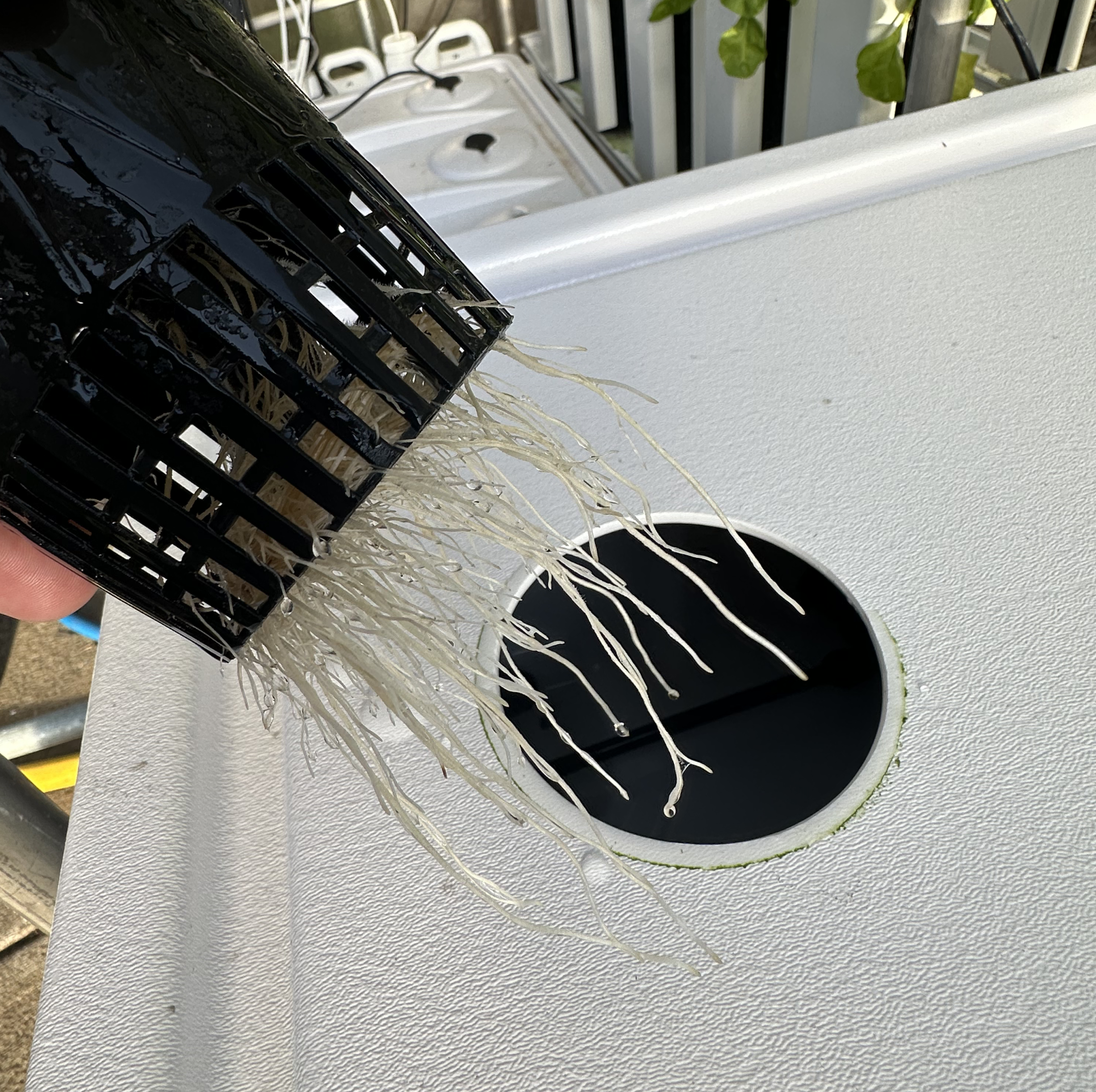

- Method of cultivation: High Pressure Aeroponics

- Type of crop: Chilli Peppers, Tomatoes, Leafy Greens

The Customer's Challenge

-

Maintaining consistent environmental conditions within a greenhouse can be complex and demanding. Our client needed a solution to:

- Precisely monitor all critical environmental factors.

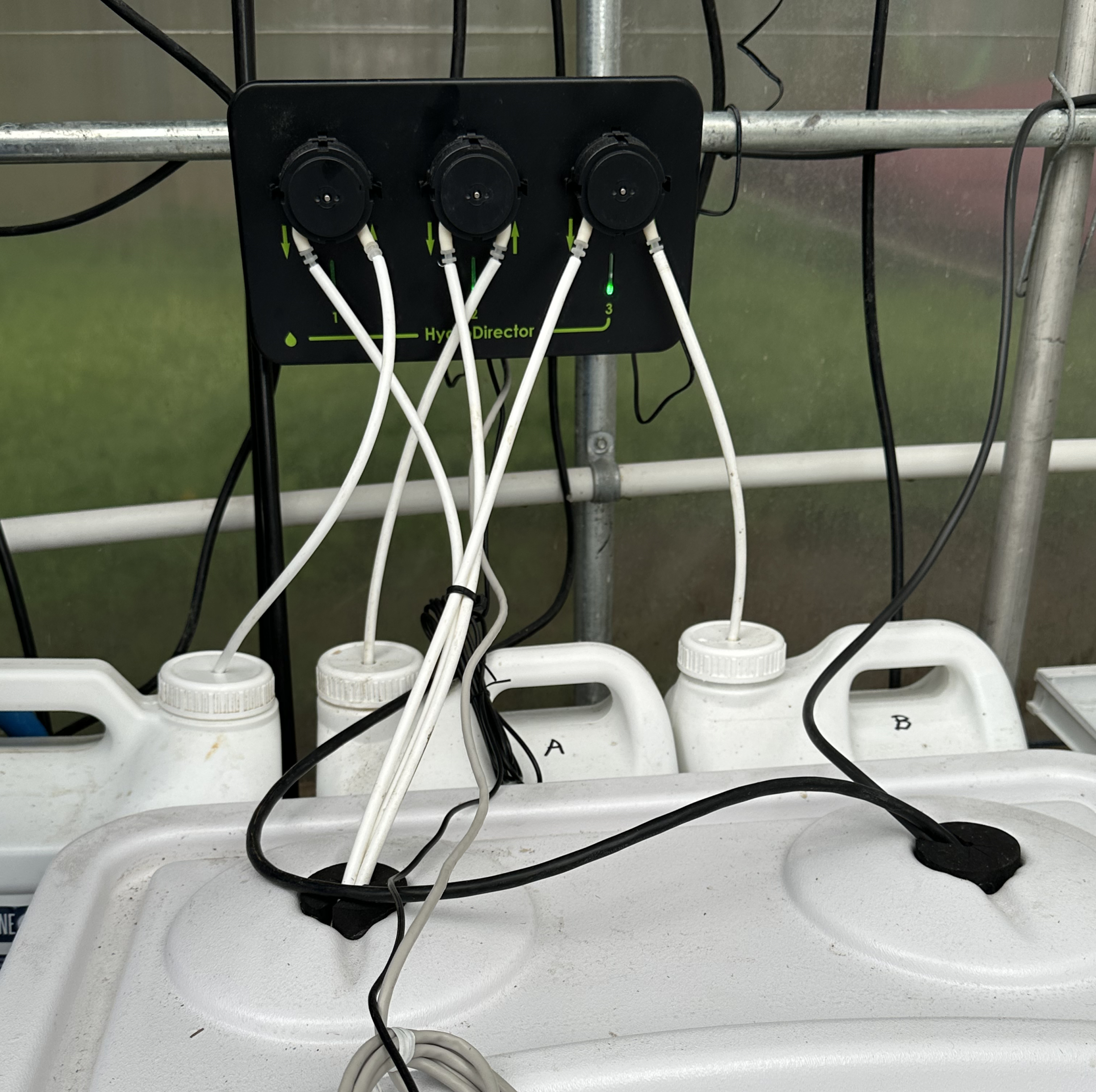

- Automate lighting, ventilation, and irrigation schedules.

- Improve labor efficiency and reduce the risk of human error in environmental management.

GrowDirector’s Solution & Result

-

By automating key processes and providing real-time data insights, GrowDirector enabled the grower to:

- Achieve precise control over temperature, humidity, lighting, and irrigation.

- Optimize environmental conditions for specific crops and growth stages.

- Streamline operations and reduce labor costs through automation.

Equipment used in the case

No data was found

Implementing GrowDirector transformed the grower’s operational efficiency and crop performance. They reported:

- Increased Yield: Optimized growing conditions led to a significant increase in overall yield.

- Improved Crop Quality: Consistent environmental control resulted in higher-quality produce with improved uniformity.

- Reduced Labor Costs: Automation minimized the need for manual monitoring and adjustments.

- Enhanced Resource Efficiency: Precise control over irrigation and climate reduced water and energy waste.