Double up production in DWC hydroponics farm? Know How!

Project Information

- Customer: Osher Farm in New Jersey (Salem)

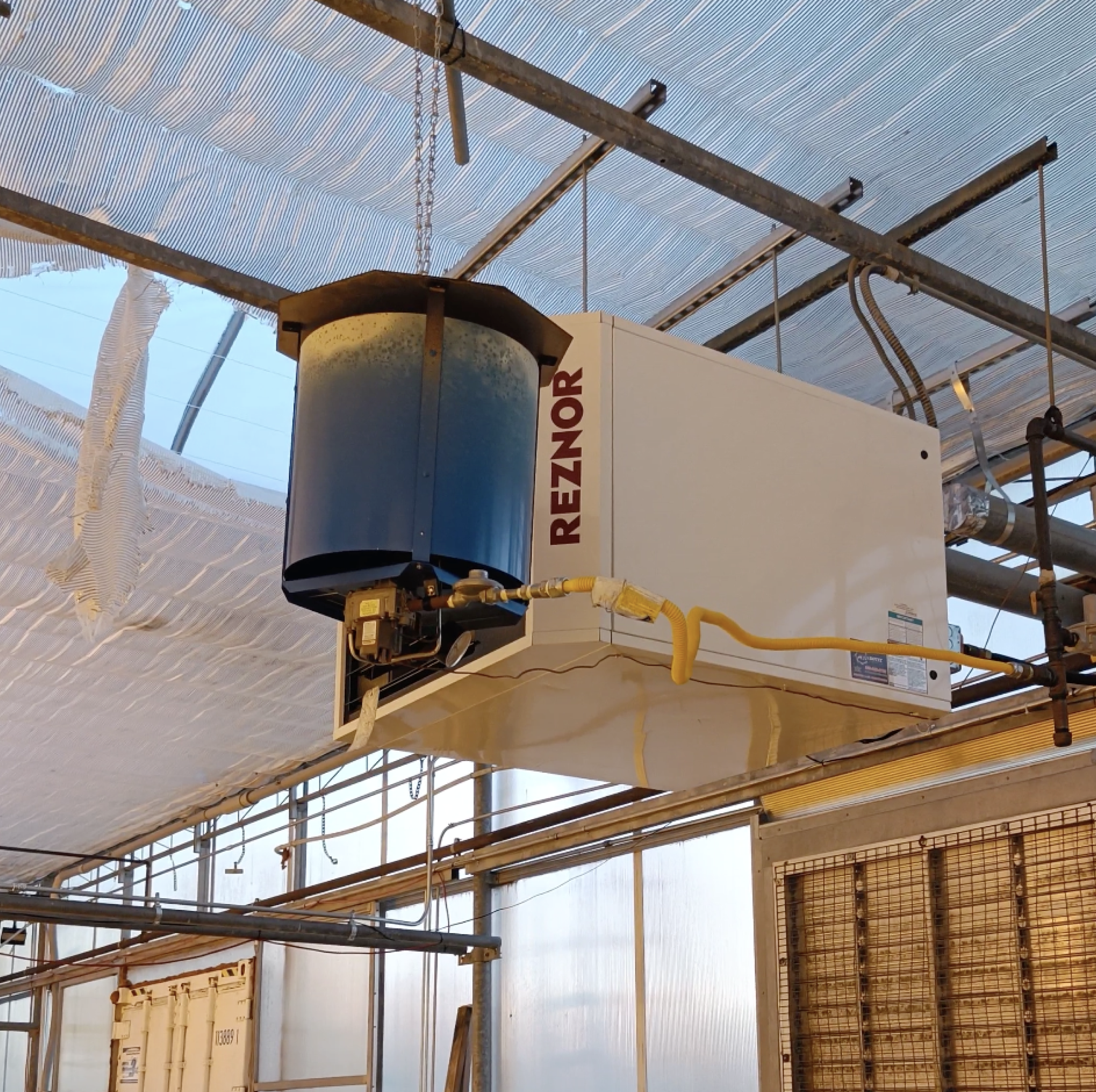

- Facility: Closed Polycarbonate greenhouse, 11,000 sqf, 5 pools of 20,000 gallons each

- Method of cultivation: DWC hydroponics

- Type of crop: Leafy greens

The Customer's Challenge

-

This DWC hydroponics farm faced challenges due to a lack of integrated automation. They had many different devices with no connection between them, leading to manual control and inefficient processes. This resulted in:

- Inconsistent environmental conditions and nutrient management.

- Increased labor costs and potential for human error.

- Difficulty in scaling operations and optimizing production.

GrowDirector’s Solution & Result

-

GrowDirector implemented an automation solution that streamlined DWC hydroponic system and provided precise environmental control. This included:

- 5 HydroBasic Kits were installed to automate nutrient delivery, pH balancing, and water level control in each pool.

- GrowDirector integrated with the existing HVAC system to automate temperature, humidity, and ventilation control within the greenhouse

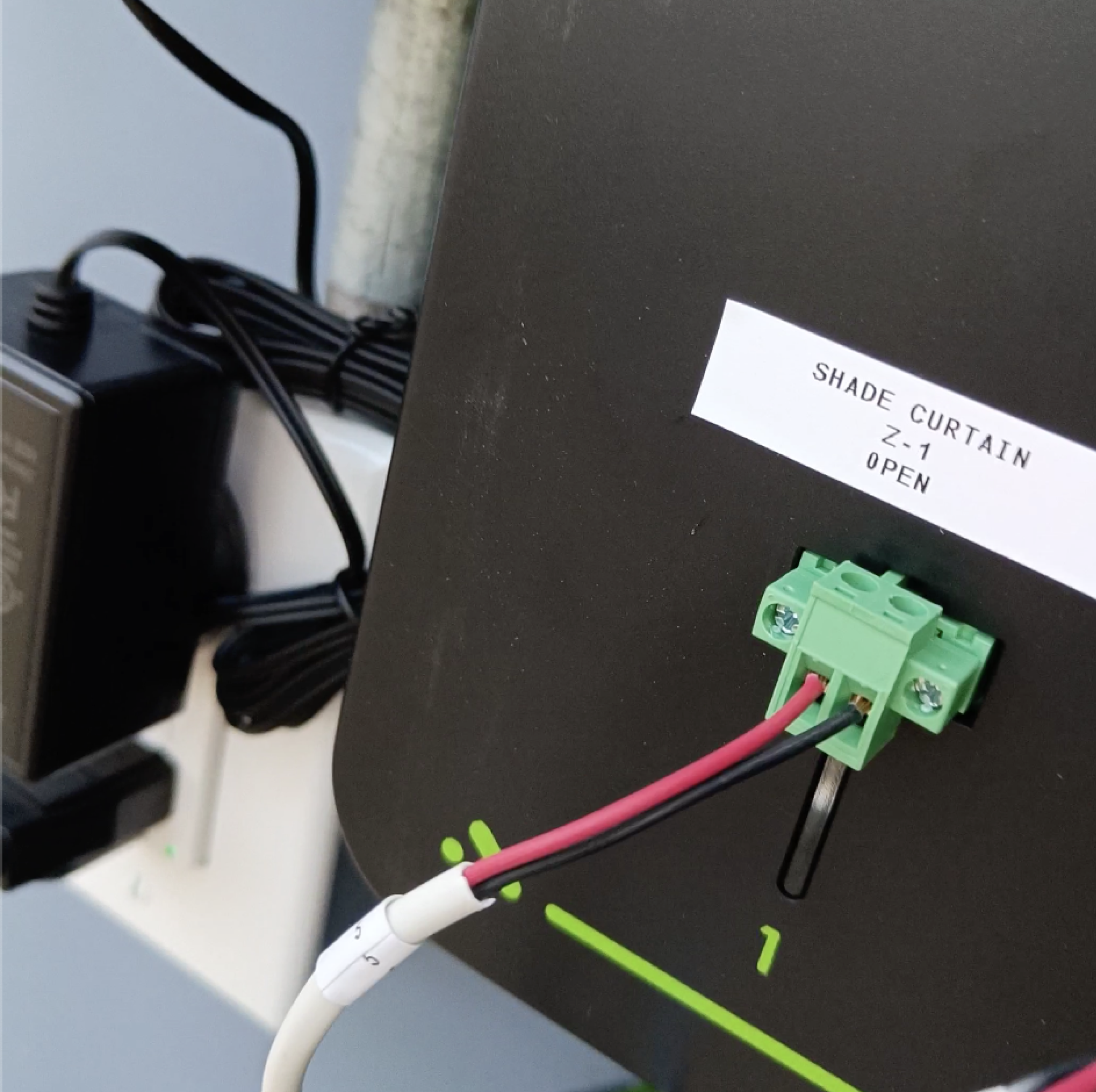

- 3 DryContactDirectors, 1 SocketDirector, 1 SensorDirector, and various sensors were deployed to monitor and control all critical environmental parameter

Equipment used in the case

No data was found

Osher Farm Testimonial

Just wanted to share some feedback that really impressed our team. We know greenhouse automation and precision agriculture can optimize many things, but we were shocked that the client saw his harvest double in just one month.

What is DWC Hydroponics? Deep water culture (DWC) hydroponics is a soilless growing method where plant roots are suspended in a nutrient-rich, oxygenated water solution. This method, also known as deep water culture hydroponics or a DWC hydroponic system, allows for rapid nutrient uptake and accelerated growth. It's a popular technique for cultivating leafy greens and other fast-growing crops because of its efficiency and yield potential. DWC hydroponics requires precise management of environmental factors and nutrient levels for optimal results.

The farm struggled with inconsistent environmental conditions due to manual control. This resulted in fluctuating yields and increased labor costs.

With the GrowDirector system in place, the farm achieved stable environmental parameters, leading to consistent, high-quality yields. Automation significantly reduced labor requirements, freeing up the grower to focus on other aspects of the business.