60% Off Labor Costs: Easy Ways to Farmstand Lettuce Grow

Project Information

- Customer: Huge Commercial Hydroponic Lettuce Farm

- Facility: Closed Plastic Greenhouse, 85,000 sqf

- Method of cultivation: DWC

- Type of crop: Lettuce

The Customer's Challenge

-

🔻Manual tasks such as pH & EC checks, fertilizer mixing, and equipment monitoring were performed by workers every few days, leading to inconsistencies and potential human errors.

🔻Furthermore, illnesses or forgetfulness among workers caused additional disruptions to their routine operations.

GrowDirector’s Solution & Result

-

We placed a tank near the fertilizer area to collect water from each DWC pan.

👉Our smart sensors checked water quality in every pan, and our system figured out what to do next.

👉Automating everything made the farmstand lettuce grow smoother and more reliable.

👉The result – 60% Off Labor Costs

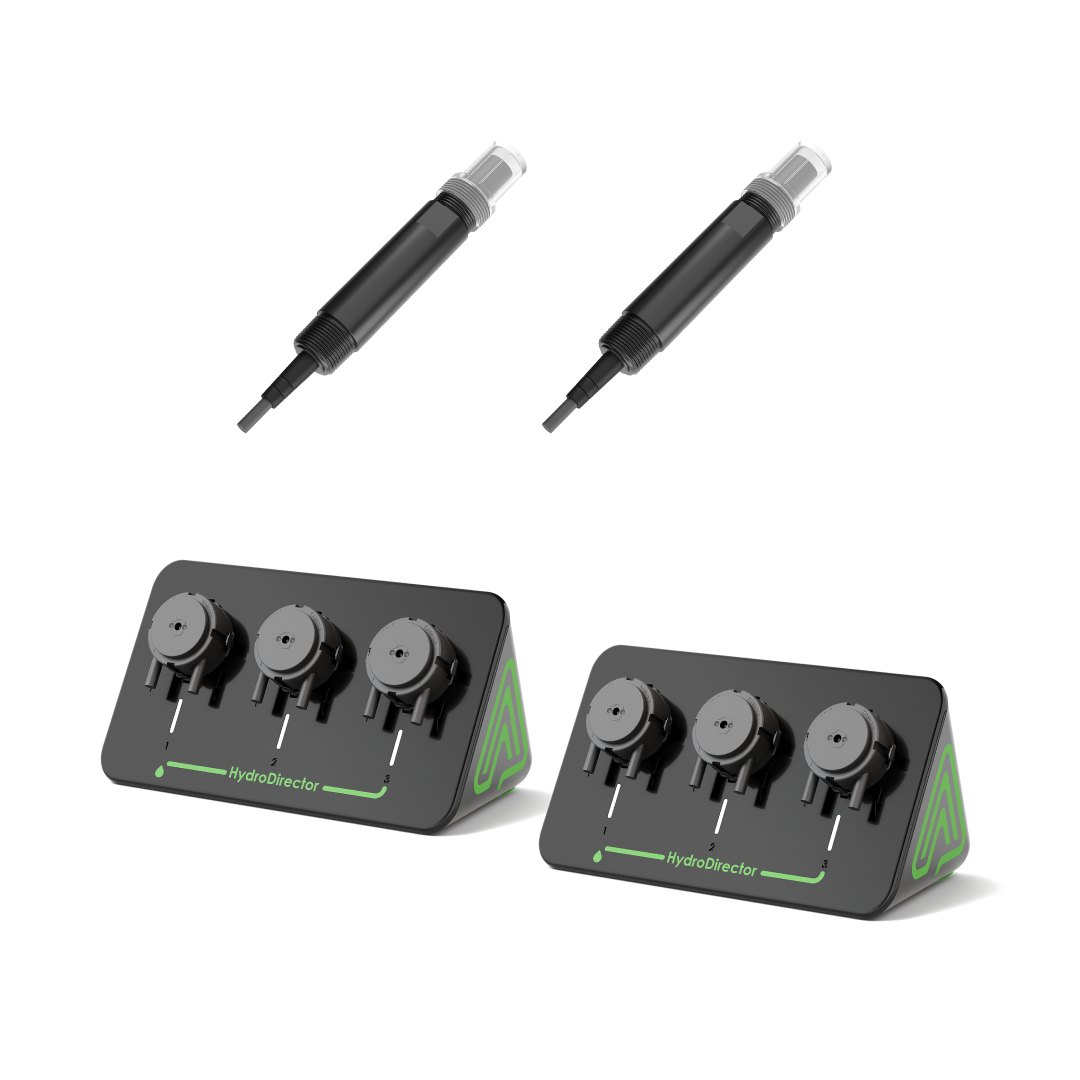

Equipment used in the case

ULTIMATE INDOOR GROWING SYSTEM

Results:

✅ The implementation of GrowDirector’s system put the customer’s worries to rest, ensuring that their harvest was in safe hands.

✅ With automated monitoring and adjustments, they experienced improved accuracy in pH & EC levels and precise fertilizer dosage.

✅ The elimination of manual labor reduced the risk of human errors and provided a more reliable, consistent growth environment.

GrowDirector in hydroponic farming